views

- Buying (or building) a 3D printed home is identical to buying a traditional building—you take out a mortgage and bid on the property.

- 3D homes are not particularly common, but this is changing rapidly. Expect to see more and more 3D printed homes in the future.

- 3D printed homes are cheaper to build, faster to build, and more environmentally friendly than their wood-framed counterparts.

How do you purchase a 3D home?

You buy a 3D printed home with a mortgage, like any property purchase. You can purchase a 3D home that has already been constructed and is listed on the open market. Alternatively, you can contact a 3D home builder to plan and build your dream home from scratch. Regardless, the process is identical to normal home buying—you secure a mortgage to purchase the property. The only potential difference will be the permitting for a 3D home (if you plan to on building from scratch). Some cities have unique permitting requirements for 3D homes. The tricky part of buying a 3D home is finding one. There aren’t that many of them out there right now.

How do I find a 3D printed home to buy?

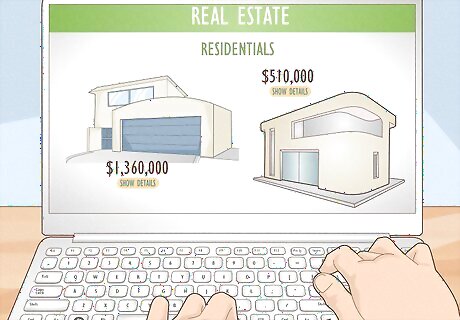

You find 3D printed homes on traditional markets, but they aren’t common. You’d find 3D homes on the same housing platforms and developer websites where you’d find traditional homes for sale. However, these 3D printed homes aren’t easy to find right now. The technology is too new and there aren’t that many companies who are building them yet. It was 2021 when the first 3D printed homes went on the market, so we’re just on the edge of brand-new market.

When will 3D printed homes be more common?

More 3D printed homes should be available after 2023-2024. There are currently several large 3D printing housing projects slated to be completed by 2023, so if those are successful, we can expect to see more of these buildings in the future (i.e. starting in 2024). It will simply take time for more and more companies to start building these kinds of homes.

Is it cheaper to buy a 3D printed house?

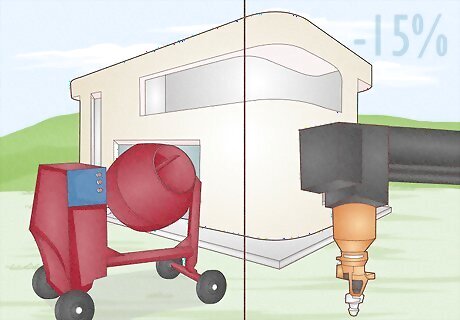

In theory, it should be cheaper to purchase a 3D printed home. 3D homes cost about 15% less to build when compared to typical single-family homes. As a result, 3D homes should be a fair bit cheaper than their counterparts. However, a lot of the pricing comes from market demand, so a 3D home may still be very expensive if you’re in a competitive market. The same logic applies whether you’d be buying the home on the open market or working with a developer to build a home from scratch. If the price of lumber drops dramatically and demand in the housing market dries up, it’s possible that 3D printed homes become more expensive than normal housing. It’s not particularly close right now, though.

Who builds 3D printed homes?

SQ4D. Working out of New York, SQ4D’s claim to fame is that they’re able to print a home in hours, not days or weeks. Their current projects are all in New York state, and they manufacture one of the most popular 3D printers other companies use to build their homes. You can reach out to them here.

3Strands. 3Strands, located in Texas, created the first 3D homes that were available for purchase in the US—the 17th Street Residences. You can ask them about their available projects here.

WASP. WASP is a cutting-edge company in Italy that is developing a dome-style housing system that may be 100% sustainable (it uses materials found on site). They’re still in the design stages of their housing system, but you can learn more here.

ICON. Located in Texas, ICON is printing 100 homes along the San Gabriel River, in the hills of Georgetown, Texas. The small settlement will be entirely self-sufficient and powered by solar energy. If you’re interested in potentially reserving a home, you can check ICON out here.

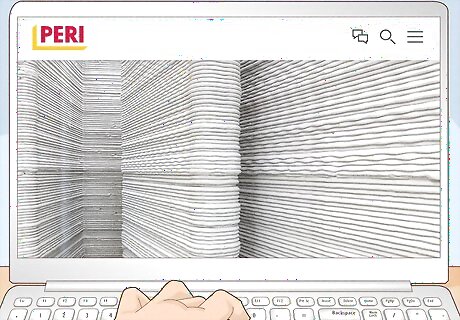

PERI Group. The German company PERI Group is perhaps the most likely builder to come to you, considering they’ve built 6 homes across 2 continents. You can reach out for more information here.

APIS. APIS, a housing company in Florida, specializes in tiny homes, and their mission is to end the housing affordability crisis. By 2023, they’ll have building projects available in Waco, TX, Birmingham, AL, Griffin, GA, Billings, MT, and Goleta, CA. You can reach out to learn more about their offerings here.

Are 3D homes like traditional housing?

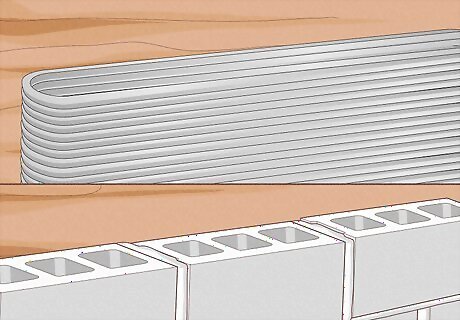

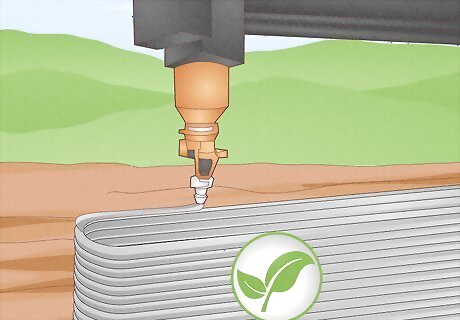

Yes, the only real difference with 3D homes are the walls. Traditional homes are stick-framed, meaning that construction workers frame the house with wood, then attach the insulation and drywall. On the exterior, they’ll lay bricks, install siding, or spread stucco. 3D homes, on the other hand, are built by giant printers laying concrete. The walls are constructed by pure concrete, then the interior is finished by hand. It only takes 2-3 days for a 3D home to be framed, while stick-framing traditionally takes 5-8 weeks! It’s not like the entire home is printed—it’s only the walls. Technicians go in after the walls are built and install the plumbing, finishes, flooring, electrical, and all the other stuff that goes into making a house livable.

Why are people excited about 3D printed homes?

3D printing homes may help solve the lack of affordable housing. There are some huge problems with housing costs right now. There are a lot of people who want to buy a home and can’t because there isn’t enough supply, which drives prices higher. 3D homes may be the key to the future. They’re faster and cheaper to build than traditional housing, so it could be a major innovation.

It’s a lot less work to build a 3D home. Building a traditional wood-frame house is dusty, dirty, loud, and burdensome. It requires a whole lot of workers hauling a ton of material. A 3D printed home really just requires one large 3D printer and a few technicians. It’s so much faster and so much less work that it’s hard to justify doing it the old way if you’re given a choice. Framing a 3D home is 75-90% faster than framing a home using the traditional methods.

It’s more environmentally friendly to 3D print a home. There’s a lot that goes into traditional home building that isn’t good for the environment. While the lumber that goes into a home is renewable, the insulation and exterior materials are not. There’s also a ton of gas consumption that goes into all those rigs, cranes, and bulldozers. 3D printing is just a lot better for the environment. Concrete walls are more energy efficient when it comes to insulation, heating, and cooling, so you’ll spend a lot less on utilities, too.

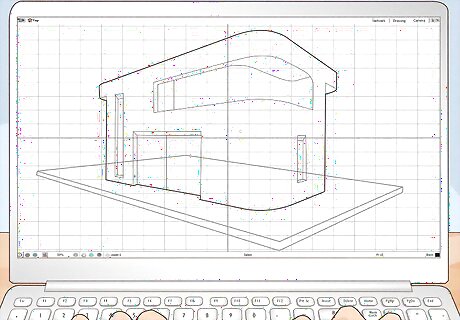

A 3D printing company can easily customize housing designs. Concrete offers a lot more flexibility than wood when it comes to structural integrity, so 3D printing companies can do some really neat and unique things that their counterparts can’t. From spherical domes to unique corners and shapes, a 3D printer can do a lot more than traditional wood framing.

Comments

0 comment