views

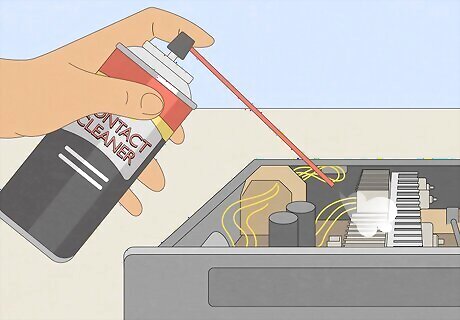

- Opt for a plastic-safe contact cleaner to safely clean vintage stereo equipment without harming its delicate internal components.

- Use a small amount of contact cleaner to remove oxidation and corrosion from jacks, plugs, switches, pots, faders, and removable connectors.

- Remove dust from the stereo's interior with short bursts of compressed air.

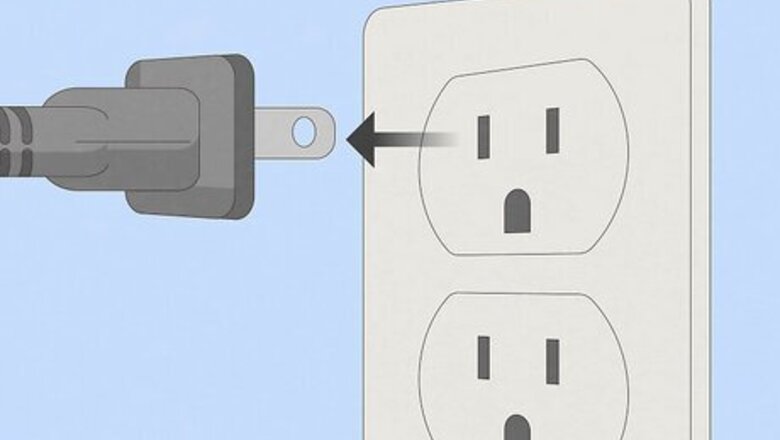

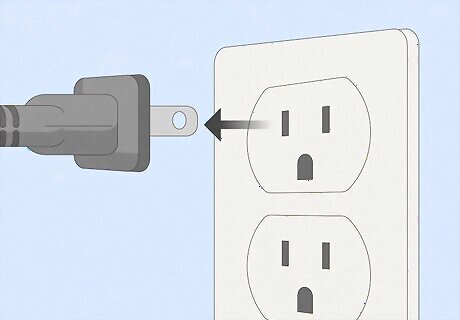

Unplug your stereo equipment. To make sure that no electricity will flow through the internal components while you clean, unplug all components. Do not simply turn the power switch off; remove the plug entirely from the wall outlet, as serious injury or death could otherwise occur.

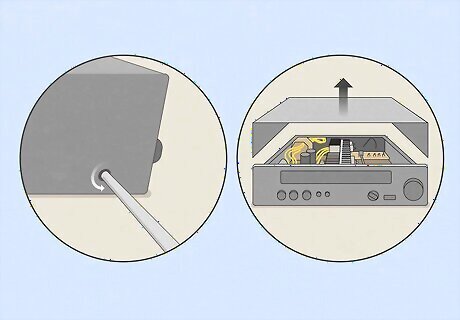

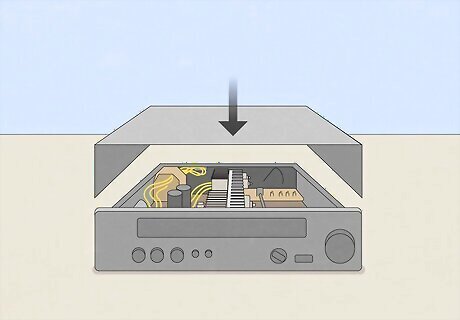

Remove the cover of the stereo component. The case is usually removed by loosening a few small screws or bolts. Often these screws will be found on the sides, back, and bottom of the unit. Not all screws on a given surface are for the casing, so look carefully at what you are unscrewing to only remove the casing screws. After removing them, set them aside or put them into numbered containers to match them up with the correct holes. You can put stickers on afterward; taking pictures can help, too. Gently lift the case away from the chassis. Warning: If you've been using the stereo, be sure to discharge the capacitors before handling to avoid electric shock. You can do so by laying an insulated screwdriver (the kind with a rubber or plastic handle) across both terminals of each capacitor.

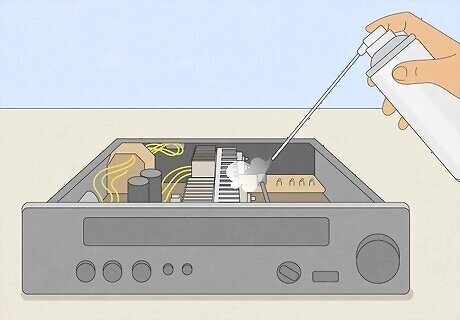

Spray compressed air throughout the unit's interior if needed. If the interior components look particularly dusty, you can clear away the dust using a spray can of compressed air. Do not attempt to wipe dust away using a cloth, as a clumsy hand can easily dislodge or damage delicate electronic components or scratch a shiny plastic faceplate.

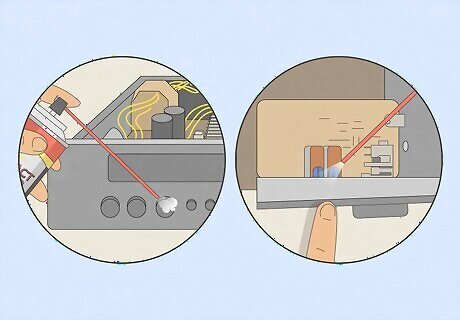

Spray contact cleaner on parts sparingly. Contact cleaner can remove corrosion or stubborn dirt from many of the stereo component's internal parts, but typically, you should only clean contacts that cause problems beyond looks. Spray a fine, even coat of the contact cleaner on problematic components, such as those with oxidation, and a thicker coat in areas with significant corrosion. Spray jacks, plugs, switches, or removable connectors that are not soldered. Always wear safety goggles to protect your eyes when using contact cleaner. Cleaning battery contacts may require additional friction to clean. You may need to replace the contacts if they've been eaten away by alkaline battery acid. Avoid spraying things that should not be sprayed, such as rubberized belts, friction wheels, pulleys, motor shafts, meter displays, light bulbs, audio or video heads, and window or dial faces. Good luck cleaning any of those off if they get a mist on them. Avoid flooding your high-voltage power switches with contact cleaners, as they rarely need to be cleaned and are safer to replace if they do. Soaking these switches is dangerous and could cause them to ignite.

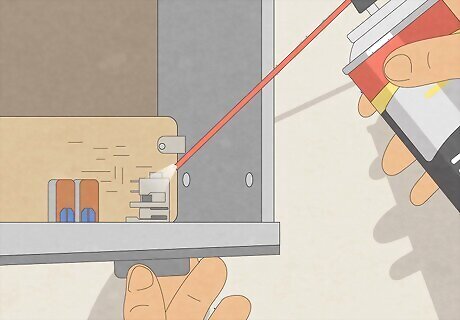

Clean the potentiometers with contact cleaner. The pots, or knobs, are the components most likely to display corrosion. To clean them, find the small hole in the back assembly of the pot or typically larger opening where the pins are soldered to the board. Spray some contact cleaner sparingly into the hole or the openings (there are typically two separate openings for stereo potentiometers), and then work the knobs back and forth frequently for about a minute. This will spread the contact cleaner throughout the inside of the pot.

Clean the faders and buttons as you did the pots. To clean faders and push buttons, you'll have to sometimes spray the contact cleaner behind the controls from the front of the unit if access is impossible from the inside without major disassembly. After spraying the cleaner, push the button or slide the fader back and forth for about a minute. Any excess cleaner that drips down the faceplate of the unit can be wiped away with a microfiber scratch-resistant cloth.

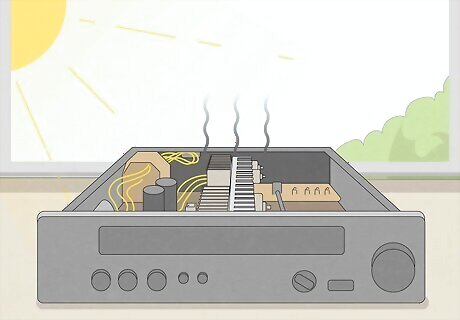

Allow the unit to air out for several hours. After applying contact cleaner to any part of your vintage stereo equipment, let the unit sit with the case off for a few hours. This helps ensure that all the contact cleaner has dried.

Replace the component's case. Replace the case gently, and secure it using the screws or bolts you removed, screwed back together first by fingertip, then by screwdriver. Be certain not to force or over-tighten, as this can strip the threading and certainly crack any plastics easily. Remember the force required to undo the screws in the first place? Only after the case is back in place should you plug the audio equipment back in and test it. Any extra screws should mean rechecking your assembly because every screw is there for a reason. Good luck!

Comments

0 comment