views

Purchasing a Crimper

Purchase a ratchet crimper for simplicity and durability. Ratchet crimpers have a built-in ratchet, which means all you have to do is apply enough pressure to the handles and the crimper will do the rest. These tools also have wider jaws, which helps them cover more connector surface area. Buy ratchet crimpers from home hardware stores or online suppliers.

Buy a manual crimper for a cheaper but less effective option. Manual crimpers can give you the same results as a ratchet crimp, but you have to put in more effort. While crimping, you need to take care to align the jaws on the connector as you apply pressure to the handles. Failing to align the jaws can lead to improper crimping. Not only that, but manual crimpers are much more susceptible to wear-and-tear. As with ratchet crimpers, you can purchase manual crimpers from home hardware stores or online suppliers.

Choose a crimping die that matches the wire gauge you're using. The crimping die is the piece at the top of the crimper that does the crimping, and almost all crimpers come with one. However, it's important to make sure the die is appropriate for your wire gauge, as each piece is designed for a specific range. Determine the gaugeof the wire you need to crimp and be sure you have an appropriate die. Red wire insulation is 22- to 16-gauge. Blue wire insulation is 16- to 14-gauge. Yellow wire insulation is 12- to 10-gauge. If your wire doesn't have colored insulation, check the packaging for its gauge.

Stripping Your Wire

Place ⁄4 inch (0.64 cm) of the end of the wire into the crimping die. Locate the hole designated for your wire's gauge in the crimping die. For example, if you're crimping a 15-gauge red wire, select the hole designed for a range that covers this gauge range. Make sure that the amount of wire is approximately equal to the metal barrel of the connector, which is usually ⁄4 inch (0.64 cm). Most crimping dies have color-coded holes that designate where to put specific colored wires.

Pull the insulation away to expose the bare wire inside. Apply pressure to the crimper handles and pull the tool away from the wire to rip the insulation off. The exposed wire inside should be the same length as the metal connector barrel. If you're using a manual crimper, hold the jaws of the crimper perpendicular to the wire and continue holding the crimper steadily in this position as you apply pressure to the crimper handles. Place the stripped wire beside the barrel of the connector—it should be approximately the same size or up to ⁄4 inch (0.64 cm) longer.

Twist the exposed wire together to make it denser. Grip the end of the exposed wire with your thumb and forefinger. Now, twist it either to the left or right to make it more firm and compact. Always twist the tip of the wire, even if it feels compact—this allows for a more positive connection for the connector.

Attaching the Connector

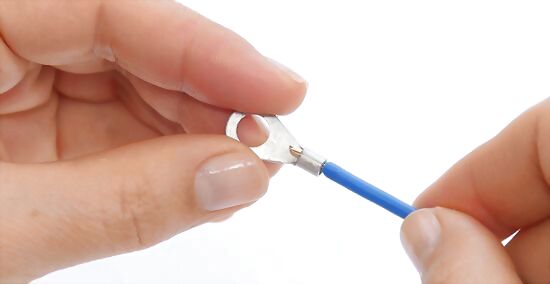

Insert the wire into the connector until the insulation touches the barrel. Carefully place the exposed portion of the wire into the connector. Continue to do so until the insulation makes contact with the barrel of the connector. Make sure the wire is not extending past the barrel more than ⁄4 inch (0.64 cm).

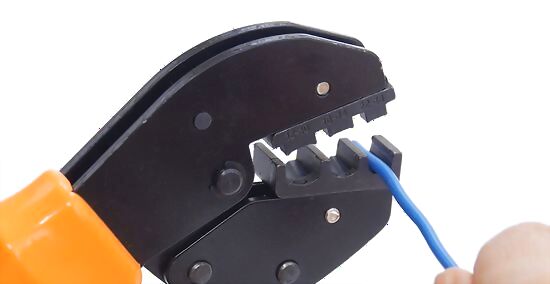

Place the barrel of the connector into the appropriate crimper slot. Place the terminal in the horizontal position with its barrel side facing upward and the flat side facing downward. Now, hold the tool perpendicular to the barrel. For tools with colored markings, match the insulation with the appropriate color on the crimper. If your crimping tool doesn't have colored markings, make sure the gauge markings on the side of the crimper match your wire's gauge. Never crimp your wire with a slot that doesn't match your wire's gauge or insulation color.

Squeeze the crimper over the barrel with considerable force. For manual crimpers, hold the tool perpendicular to the terminal and over the barrel—closer to the ring than the wire insulation. Hold the crimper steady and squeeze the handles with a considerable amount of force. Don't worry about applying too much pressure—it's nearly impossible to "over crimp." For ratchet crimpers, the crimper slot will align the crimper over the barrel automatically—simply apply pressure to the crimper handles and you're good to go! Make sure that the wire and connector are held firmly together following the crimp by tugging them apart.

Solder the wire to the connector if the connection is loose. In some cases, the connection is left loose due to a wrong wire size or connector. If you don't want to start all over, solder the joint between the connector and wire. Insert the tip of the soldering gun into this location and apply a small amount of solder until it connects the wire and connector. Clean the tip of the soldering iron if it gets messy to ensure the connection is as clean as possible. Use a 30-W to 60-W soldering iron that can solder at 500 to 600 °F (260 to 316 °C) for the best results.

Seal the terminal with electrical tape or heat shrink. Use a pair of scissors to remove a small piece of electrical tape big enough to cover the crimp terminal. Wrap about 2 layers of tape over it to help prevent the metal from corroding. Always seal the terminal when your connection is going to be exposed to heat, snow, wind, or rain.

Comments

0 comment