views

Protecting Yourself

Wear thick work gloves. Your hands will be working with the fiberglass during the entire process, so it's important to keep them covered. Wear thick, durable construction gloves when handling, and especially while cutting, the fiberglass.

Wear loose, long-sleeved clothes. When cut, fiberglass particles may enter the air and lead to rashes and body irritation. Sharper particles can even scrape or tear the skin. To avoid this, wear loose, long-sleeved clothes that cover but don't stick to your skin. To protect against unintended cuts, make sure to tuck in your shirt and avoid clothes with dangling sleeves. Another alternative to fully cover your body is to wear a Tyvek suit.

Wear goggles for eye protection. Your eyes can experience severe irritation when exposed to fiberglass particles. To keep yourself safe, wear clear goggles or similar protective eyewear when working. If you wear prescription glasses, make sure to put a pair of goggles on over them.

Wear a dust mask. When inhaled, fiberglass particles can lead to general soreness, throat inflammation, and long-term breathing and lung complications. To protect your nose, mouth, and throat, wear a snug dust mask when working with fiberglass. If available, use a respirator mask designed specifically for woodworking and sanding.

Work in a large, open space. When cutting fiberglass, make sure you're working in a clear, spacious area such as your driveway, garage, or a woodshop. If inside, make sure a door or window is open so dust particles can escape.

Slicing Fabric

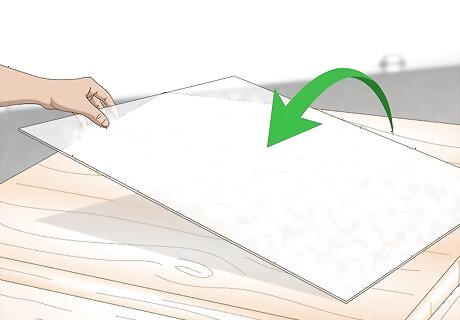

Place the cloth on a hard table. Stretch your sheet of fiberglass out over a hard, flat working table. Make sure the area is clear of any debris, including small things like pencil shavings and dust. If your fabric is still on a roll, pull out only the amount you plan on cutting.

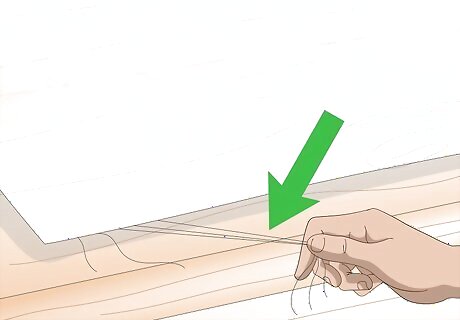

Pull out fabric strands along the cutting edge until one lasts the length of the sheet. If your fiberglass has been cut previously, the bottom edge will have some light fraying on it. To give yourself a clean sheet to work with, pull out frayed strands until one of them remains unbroken from the left side of the sheet to the right. This will ensure that the fabric you're cutting is made of full, durable fiberglass strands. Repeat this step after every cut, even if the edge looks straight.

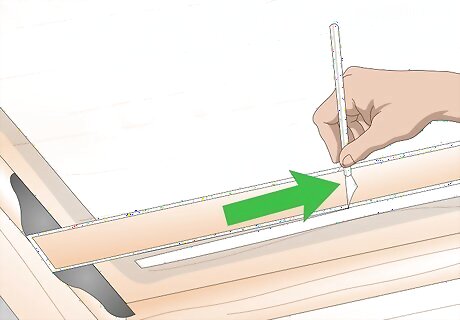

Square up the fabric with the edge of the table. Place a large drafting ruler or t-square along the cutting edge of the fabric, covering up any crooked elements to create a solid, straight line. For ease of cutting, make sure the sheet is parallel with the table itself.

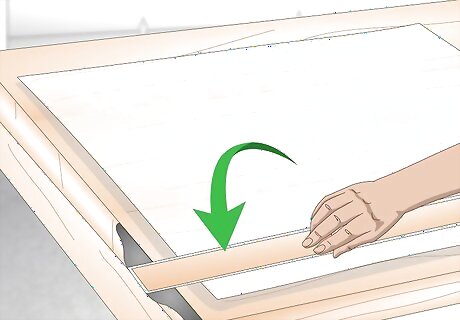

Smooth out the fabric by gently spreading your hands over it. To get out any bumps or creases, smooth out the fiberglass using the palms of your hands. Push away from the edge to avoid adding wrinkles to the part you plan on cutting.

Use shears or an X-ACTO knife to cut the fiberglass. Move your ruler or t-square to the line of fabric you want to cut. Using heavy duty shears, an X-ACTO knife, or a similar precision blade, cut a thin, straight line through the fabric.

Cutting Straight Lines in Panels

Place your fiberglass panel on a safe working table. Set your panel on a thick, sturdy working table. You will cut along the edge, so look for tables that are solid or bolted to the ground. Avoid lightweight tables that move easily. If you need to cut your fiberglass down the middle, place it across two tables with the center hanging in the air.

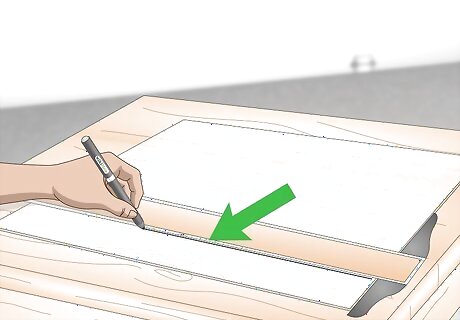

Draw a line through the area you plan to cut. Use a ruler or level to make sure your panel is straight and lined up with the table. With a pencil or marking pen, draw a line through the area you wish to cut. This will help you navigate while sawing.

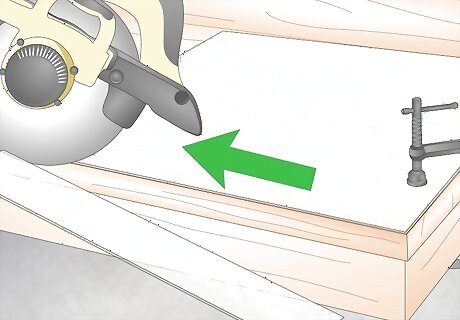

Clamp your panel down to hold it in place. Use handheld or woodworking clamps to secure your fiberglass to the table. Make sure your clamps are fully tightened and attached firmly to the table, that way they won't slip off while you're sawing.

Use a circular saw to cut straight lines. Position your circular saw at the beginning of your drawn line. Cut into the fiberglass gently to make sure the blade is deep enough. If it is, continue guiding the saw through the entire panel. Hold the saw firmly and make sure your pressure and speed are consistent. If your saw kicks or jitters, turn it off and hold it in place. Give it a moment to rest before continuing.

Making Curved Cuts in Panels

Set your panel on a strong working table. Secure your fiberglass to a sturdy, bolted down working table when making cuts. If you are sawing through the middle of a panel, lay your fiberglass down across two working tables.

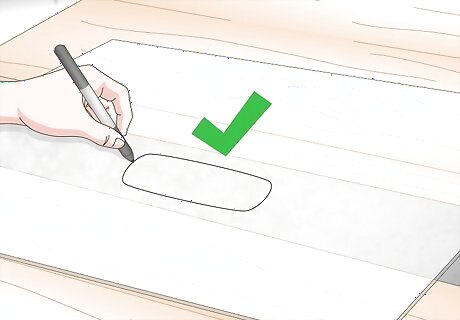

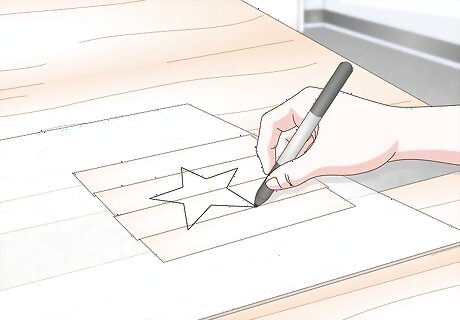

Mark the cutting line with a sharpie. Use a dark colored marker or sharpie to draw a precise line over the area you intend to cut. Because curved lines are more difficult to follow than straight ones, make sure it is clear, bold, and easy to see.

Drill ⁄16 inch (0.79 cm) holes at the beginning and end of your cut line. This will give your saw an area to enter and exit easily. Use a power drill to create clean holes in your fiberglass panel. For cuts you find particularly long, make holes along the line to increase your precision and give you specific areas to take a break.

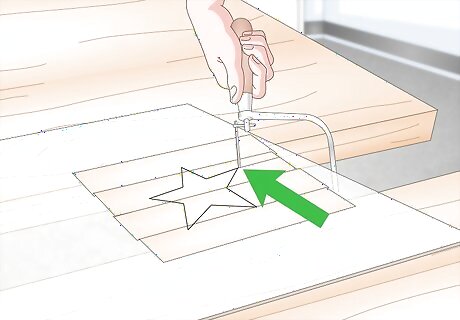

Place a fine-toothed jigsaw into the first hole and pull it toward you. Slowly and steadily pull the saw along the cutting line, turning it as necessary. Do not force it: let the blade do all the work while you simply direct and keep it steady.

Use a mill file to clean the cuts. Jigsaws are messy machines, so you may need to file down the new opening to remove flaws created by imprecise turns or accidental cuts. Using a fine-toothed mill file, push down on the edge of the cut fiberglass. Do not pull up on the file as doing so could damage the material's surface. You do not need to file much, just remove the outermost flaws.

Sawing Small Pieces and Panels

Use a solid working table. When dealing with small pieces of fiberglass, place your panel on a sturdy working table. Though it does not need to be as high-quality as those used for miter saws and jigsaws, make sure it does not wobble and can keep the panel firmly in place.

Wrap masking tape around the area you intend to cut. Since you are dealing with smaller segments and a handheld saw, cover the area you plan on cutting through with a layer of masking tape to avoid chips or splinters. Make sure the tape extends at least 1 inch (2.5 cm) beyond the spot in question.

Mark the tape with a cutting line. Use a small pencil to mark the line where you intend to cut. Because the panel is covered with tape, double check to make sure the line is accurate and matches all your measurements.

Line up a hacksaw with the marked line. Place the back edge of a fine-toothed hacksaw blade directly against your cutting line. To make sure you don't get injured, hold the saw so its handle is pointed toward yourself, protecting your body from the blade.

Pull the hacksaw back and forth to make the cut. In slow, steady motions, pull the hacksaw toward and away from yourself to saw through the fiberglass. This may take some time, since the hacksaw is a manual tool. To make sure the panel is cut cleanly, do not rush the process.

Comments

0 comment