views

Checking for a Charge

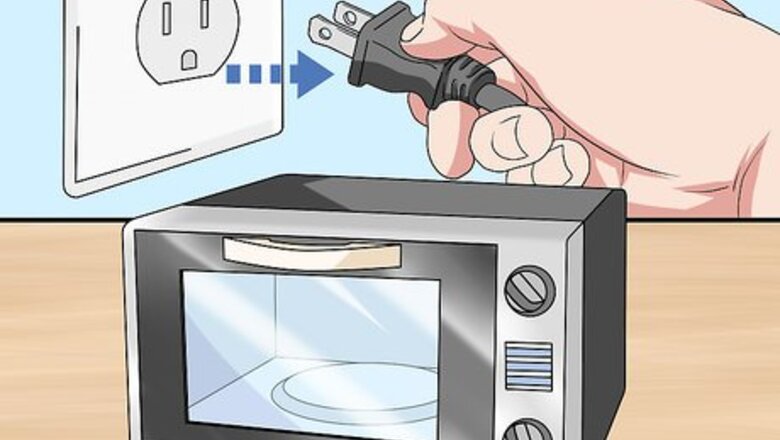

Disconnect the capacitor from its power source. If the capacitor isn’t already removed from whatever you’re working on, ensure you’ve disconnected any power source leading to it. This usually means unplugging the electronic device from the wall outlet or disconnecting the battery in your car. In a car, locate your battery in the engine bay or trunk, then loosen the nuts holding the cables on the negative (-) and positive (+) terminals using an open-ended wrench or socket with a ratchet. Slide the cable off of the terminal to disconnect it. Wrap the end of each cable with a rag so they don’t touch anything. In your house, you can usually unplug the device you’re working on from the wall, but if you are unable to do so, locate the house’s breaker box and flip the switch that controls the flow of electricity to the room you’re working in.

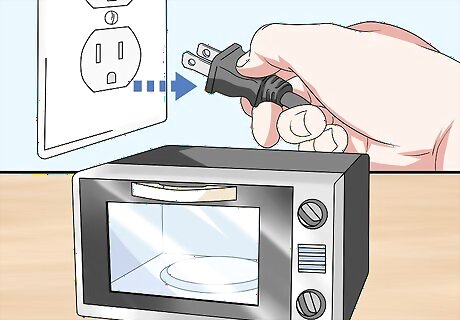

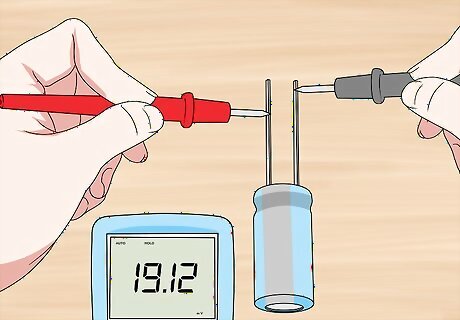

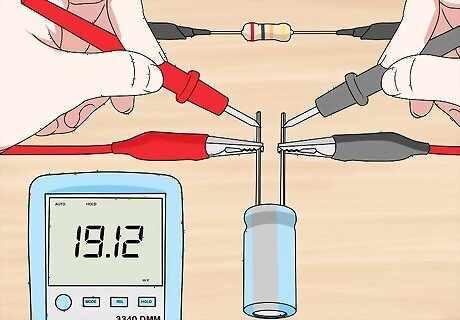

Set your multimeter to its highest DC voltage setting. Different multimeters will have different maximum voltage ratings. Turn the dial in the center of your multimeter to the highest voltage setting it will permit. Setting it to the highest possible setting will ensure you get an accurate reading of however many volts of electricity the capacitor is charged with.

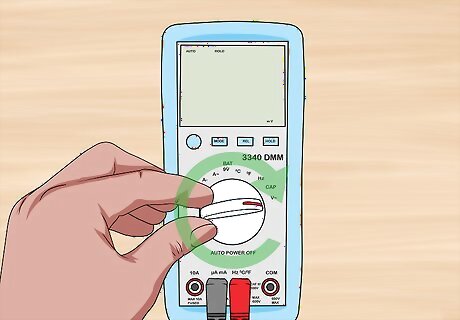

Connect the multimeter probes to the posts on the capacitor. The capacitor will have two posts sticking out of the top. Simply touch the red lead from the multimeter to one post and then the black lead to another post. Hold the leads on the posts while you read the display on the multimeter. You may need to open your appliance or remove components to gain access to the capacitor. Refer to an application specific repair manual for help if you can’t locate or access the capacitor. Touching both leads to the same post will not produce an accurate reading. It doesn’t matter which lead you touch to which post because it’s reading the level of current passing from one to the other.

Look for a reading that’s higher than 10 volts. Depending on what you’re working on, the multimeter may give you a reading that ranges from single digit voltage to hundreds of volts. Generally speaking, a charge of greater than 10 volts is considered dangerous enough to shock you. If the capacitor reads as having fewer than 10 volts, you don’t need to discharge it. If the capacitor reads anywhere between 10 and 99 volts, discharge it with a screwdriver. If the capacitor reads in the hundreds of volts, the safest way to discharge it is with a discharge tool, rather than a screwdriver.

Discharging with a Screwdriver

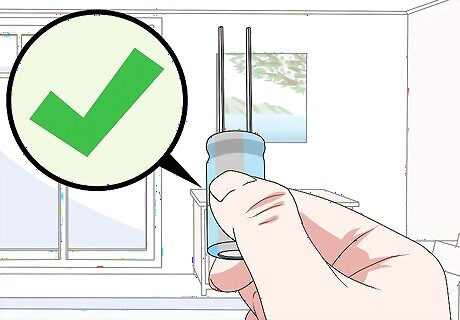

Keep your hands clear of the terminals. A charged capacitor can be very dangerous, so it’s important that you avoid coming into contact with the terminals at all times. Never touch the capacitor anywhere but on the sides of its body. If you touch the two posts, or accidentally connect them with a tool, you could get badly shocked or burned.

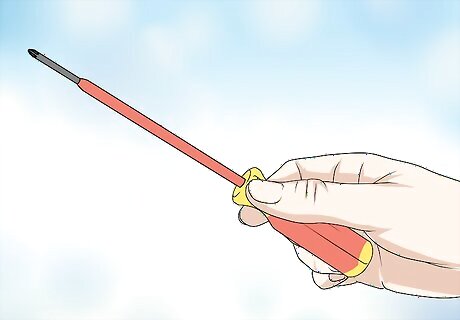

Choose an insulated screwdriver. Insulated screwdrivers usually have rubber or plastic handles, which creates a barrier between your hand and the metal portion of the screwdriver itself. If you don’t have an insulated screwdriver, purchase one that clearly states that it’s insulated on the packaging. Many will even tell you what voltage rating they are insulated against. If you are unsure whether or not your screwdriver is insulated, it’s best just to buy a new one. You can purchase insulated screwdrivers at any auto part or hardware store, as well as at most large retail stores. It does not matter if the screwdriver is a flat head or Phillips head.

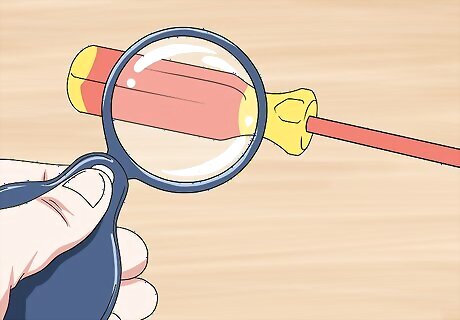

Inspect the screwdriver handle for any signs of damage. Do not use any screwdriver with a tear, crack or break in the rubber or plastic of the handle. That damage could allow the flow of electricity to pass up into your hand when discharging the capacitor. Purchase a new insulated screwdriver if the handle on yours is damaged. You don’t have to throw a screwdriver with a damaged handle away, just don’t use it to discharge capacitors or do other electrical work.

Grip the capacitor low on the base with one hand. You need to maintain total control over the capacitor while you discharge it, so pick it up low on the cylindrical body with your non-dominant hand. When you pick it up, make a “C” with your hand and fingers to grip it, keeping all of your fingers away from the top where the posts are. Maintain a comfortable grip. There’s no reason to squeeze the capacitor too hard. Keep your grip low on the capacitor to avoid contact with sparks when you discharge it. Use a pair of insulated pliers to hold smaller capacitors so you don’t accidentally shock yourself while you’re discharging it.

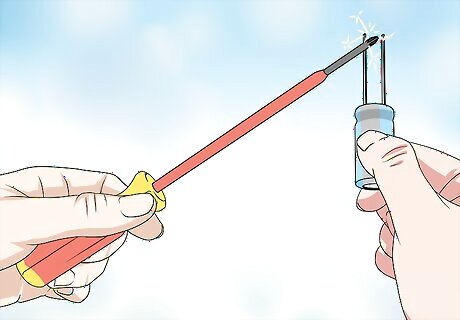

Lay the screwdriver across both terminals. Hold the capacitor upright with the posts pointed toward the ceiling, then bring the screwdriver over with the other hand and touch it to both posts at once to discharge the capacitor. You will hear and see the electric discharge in the form of a spark. Make sure the screwdriver is touching both terminals at once or else it won’t work.

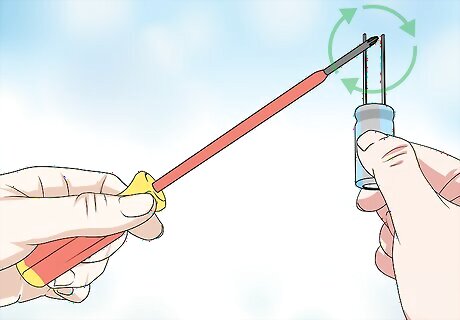

Touch it again to check that it’s discharged. Before you handle the capacitor freely, pull the screwdriver away and bring it down again onto the two posts to see if it produces any spark. If you properly discharged it, there should be no additional discharge. This step is just a safety precaution. Once you’ve confirmed that the capacitor is discharged, it’s safe to handle. You can also confirm that it has been discharged using your multimeter if you’d prefer.

Making and Using a Capacitor Discharge Tool

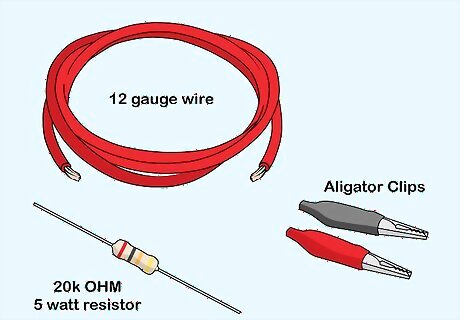

Purchase 12 gauge wire, a 20k OHM 5 watt resistor, and 2 alligator clips. A discharge tool is really just a resistor and a bit of wire to connect it to the posts on the capacitor. You can purchase all of these parts at your local auto parts or hardware store. The alligator clips make it much easier to keep the tool connected once it’s completed. You will also need electric tape or heat shrink wrap and a soldering iron if you don’t already have one.

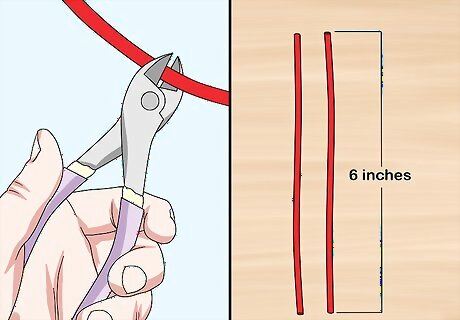

Cut the wire into two 6 in (15 cm) pieces. The exact length of the wire isn’t particularly important, as long as there’s enough slack to connect both to the capacitor and the resistor. For most applications, 6 inches (15 cm) is enough, but you can make yours longer if it helps with your specific situation. Each wire just needs to be long enough to connect one end of the resistor to one post on the capacitor. Cutting the pieces a little longer gives you some extra slack to work with and may make things easier.

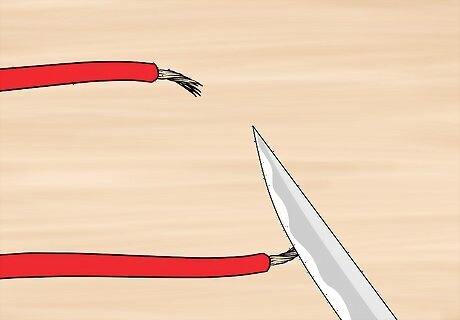

Clip off about ⁄2 inch (1.3 cm) of insulation on each end of both wires. Use wire strippers to remove the insulation without damaging the wire inside. If you don’t have strippers, you can use a knife or razor blade to cut through just the insulation and then use your fingers to pull it off the wire. Both ends of both wires should show bare metal now. Make sure to remove enough insulation to solder the stripped ends to other wires or clips.

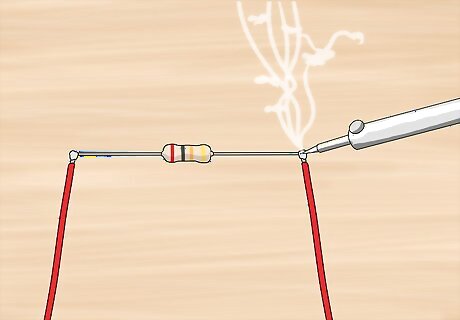

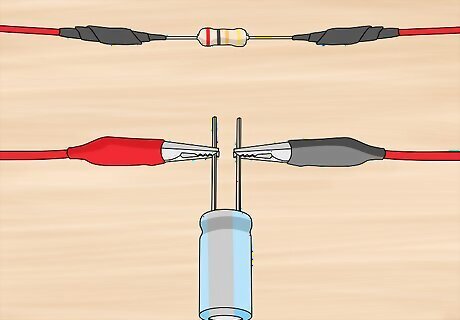

Solder one end of each wire to the two probes sticking out of the resistor. The resistor has a wire post sticking out of each end. Wrap the end of one wire around the first post and then solder it into place. Then wrap one end of the other wire around the other post and solder it into place. It should now look like a resistor with long wires sticking out of each end. Leave the loose ends of each wire free for now.

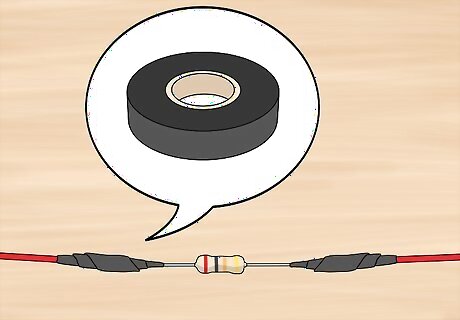

Wrap the soldered connections in electrical tape or shrink wrap. Cover the solder using the electrical tape by simply wrapping a piece around it. This will help hold the connection in place while also insulating it from anything that may come into contact with it. If you’re making a tool you will likely reuse, slide a tube of electrical heat shrink wrap over the end of the wire and slide it along until it covers the soldered connection. If you use heat shrink wrap, you can shrink the wrap in place over the connection by exposing it to the flame from a lighter or match. Do not expose electrical tape to a flame.

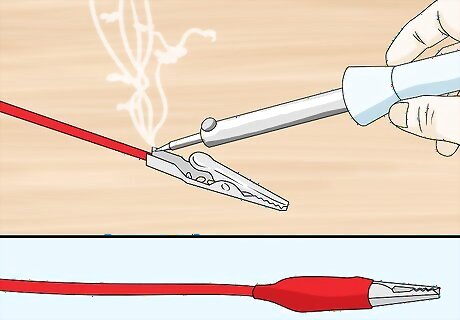

Solder the alligator clips to the ends of each wire. Take the loose end of one of the wires and solder an insulated alligator clip to it, then either heat shrink wrap it or cover it in electrical tape. Then do the same with the other loose end on the other wire. If you are going to use heat shrink wrap, remember to slide it over the wire before soldering the clip into place; otherwise, you won’t be able to get it over the head of the clip once it’s permanently affixed to the wire.

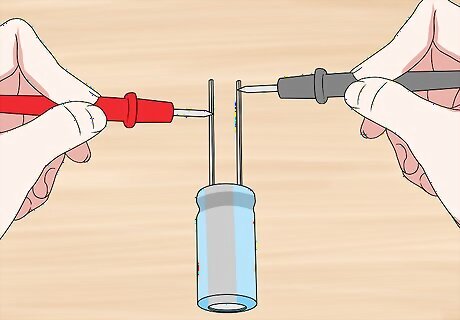

Connect one alligator clip to each of the two posts on the capacitor to discharge it. Clip the end of each wire to a different terminal on the capacitor. It will discharge very quickly, though you shouldn’t see or hear a spark as you would with a screwdriver. Be sure each clip has a clean connection with the metal of the post. Be careful not to touch the posts with your hands while you connect them.

Use a multimeter to make sure the capacitor has discharged. Once again set the multimeter to its highest voltage rating and touch each lead to a separate post on the capacitor. If it still shows stored voltage, check the connections on your discharge tool and try again. You can leave the multimeter connected to the capacitor while you watch the voltage drop in real time. If the voltage doesn’t drop, one of the connections isn’t right in the discharge tool. Examine it closely for where one might be broken. Once all of the connections on the discharge tool are good, try again and it should discharge.

Comments

0 comment