views

Setting up a furnace

Seek advice specific to your goals. While this article gives you good general instructions for melting brass, there are many factors to consider when setting up a furnace. Seek advice online or from foundry workers to find a furnace setup suitable for your budget, the volume of metal you plan to melt, and all types of metal you might want to use it for. Popular metalworking forums online include IForgeIron. The hobbyists and professionals there should be able to advise you.

Prepare a metal melting furnace. Melting brass requires a great deal of preparation, and a special furnace that can heat the brass rapidly before too much of the component metals oxidize. Purchase a metal melting furnace that can reach 2,000ºF (1,100ºC), constructed from a refractory material that can withstand this heat. Most brass will melt at temperatures as low as 1,650ºF (900ºC), but a higher maximum temperature will give you a margin of error, and make the brass easier to pour. Select a furnace large enough to hold the crucible and brass you intend to melt. Consider the fuel you will be using. Waste oil is a free fuel source, but the furnace may be more expensive. Propane furnaces are cleaner, but require you to keep purchasing more fuel. Solid fuel furnaces may be cheapest to purchase, or make yourself, but require significant fuel expense and cleanup if used frequently.

Separate out your brass items for melting. You may already have brass items ready for melting, but if you want more raw material, thrift stores and yard sales are often treasure troves. Failing that, you can try contacting local scrap yards. Remove the brass from other materials, especially non-metallic objects such as glass, plastic, paper, and cloth.

Clean the brass. Wash the brass with soapy water to remove surface contaminants such as oils and excess oxidation prior to performing the melt. If the brass is lacquered, remove the lacquer with acetone, lacquer thinner, or paint stripper. Always wear gloves and work in a ventilated area while removing lacquer, especially if using paint stripper.

Acquire a crucible. A crucible holds the molten metal while it is in the furnace. For brass alloys, a graphite crucible may be the best option owing to its durability and ability to be heated quickly. Crucibles made from other materials are available, but make sure they can withstand the high temperature required. Before using a new graphite crucible, heat it to 200ºF (95ºC) for 20 minutes and let cool. This removes excess moisture that can cause spattering. Each crucible should only be used for one alloy. If you also plan to melt aluminum, iron, or other metals, they will each need their own crucible.

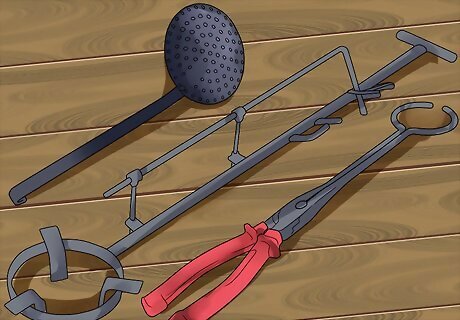

Gather miscellaneous materials. You'll need tongs, a skimming spoon, and a pouring shank to handle the metal. Steel tongs are used to grip the crucible and place it in or out of the furnace. A steel skimming spoon is used to remove dross from the surface of the metal before pouring. Finally, a pouring shank is needed to hold the crucible in place and allow you to tilt it for pouring. If you are able to weld, you may fabricate these tools yourself from scrap. Optionally, purchase a pyrometer for measuring high temperatures, to make it easier to determine when the brass is ready to pour.

Place your furnace in a well-ventilated area. An outdoor area is almost a necessity for melting brass, as the creation of toxic fumes is almost impossible to avoid. An open garage or similar structure may be a good option. Even when melting other metals, make sure your furnace has sufficient ventilation. Furnaces require a great deal of air, and may produce carbon dioxide and other gases, depending on the fuel source.

Add a box of dry sand. Even apparently dry materials, especially concrete, can contain trapped moisture. If a drop of molten metal comes into contact with moisture, the liquid will transform into steam and rapidly expand, spraying the molten metal with force. To avoid this scenario, place a box of dry sand near the furnace, and always carry and pour molten metal above this sand.

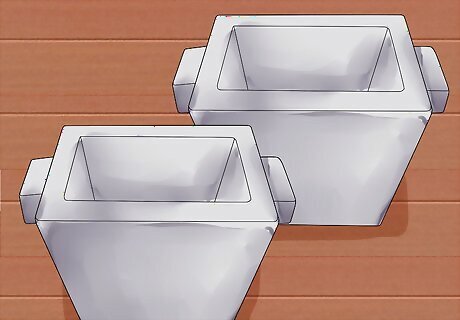

Gather ingot molds. The easiest way to handle molten brass is to pour it into metal ingot molds. Casting the brass into more complex shapes takes considerably more preparation. Look up information on sand casting or foam inclusion casting if you are interested in casting machine parts or artwork. Find expert supervision for these processes if possible, as success rate can be low for beginners.

Following safe practices

Wear heat-safe gloves, apron, and boots. Accept that melting metal in your backyard is a hobby that will probably lead to the occasional accident. This doesn't have to be a big deal, as long as you don't skimp on protection. Leather gloves, leather boots, and a heat-resistant apron should protect you from most minor incidents. These are often available as welding safety equipment.

Wear cotton or wool clothing. Wear long sleeves and long pants underneath your protective gear, to prevent molten metal drops from landing on your bare skin. Cotton and wool tend to extinguish themselves quickly. Avoid synthetic materials, which can burn for a long time or melt to your skin.

Protect your face and eyes. Wear a protective welding mask or helmet to guard your face from drops of molten metal whenever you handle the hot metal. Put on a welding mask with dark lenses any time you cast metal to protect your eyes from overexposure to UV light.

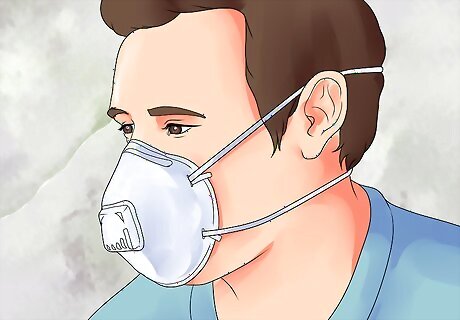

Consider a respirator. Brass is an alloy of copper and zinc, sometimes with other metals added. Zinc has a relatively low boiling point (1,665ºF = 907ºC), which is often reached before the brass is fully melted. This causes the zinc to burn, producing a white smoke that can cause temporary flu-like symptoms when inhaled. Other materials such as lead may also be present, which can cause long-term damage after repeated exposure. A respirator rated for metal fume (P100 particulates) should protect you from these dangers. Children are at higher risk of lead poisoning than adults, and should be kept well away from the furnace while it is in use.

Remove clutter from the area. All flammable and wet materials should be removed from the area, as these can cause fires and steam explosions when drops of molten metal hit them. Keep your workspace clear of all nonessential tools and objects, to give yourself a clear path between the furnace and the molds.

Know where the nearest source of water is. Don't keep moisture to close to your furnace, but do have a source of cold, running water in the same general area, or at least a large bucket of cold water. If you are burned, immediately immerse the affected area in water, without pausing to remove clothing.

Melting the brass

Heat your molds and skimmer spoon. Preheat the metal molds to a temperature above 212ºF (100ºC) to remove all moisture, or the molten metal will spatter when poured. Remove them from the heat and place them on dry sand. Preheating your skimmer spoon is also recommended, for the same reason.

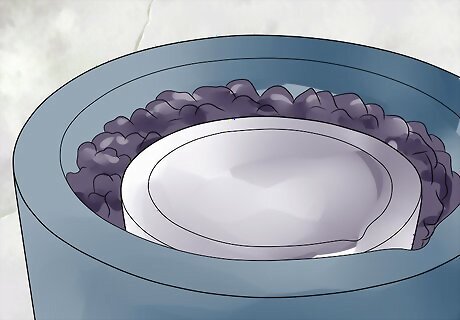

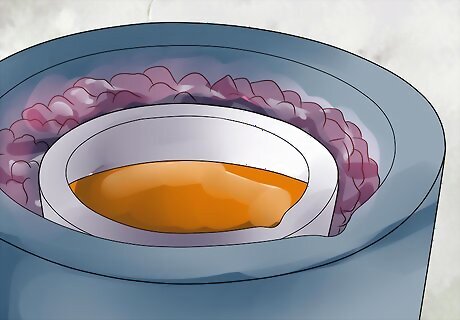

Place your crucible in your furnace. Position the crucible into your furnace. In solid-fuel furnaces, charcoal is often packed around the crucible, but follow the instructions for your furnace model or type of home-built furnace.

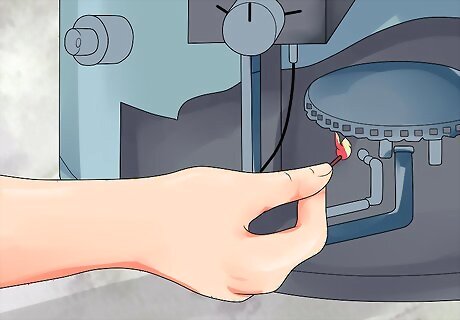

Light the furnace. Follow the instructions that came with your furnace, or follow the advice of experienced hobbyists if you built your own backyard furnace. Usually, this involves adding solid fuel or turning on the gas, then lighting it with a torch.

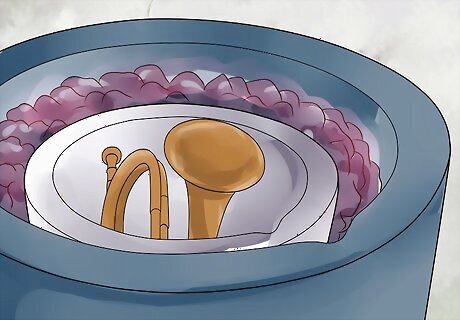

Fill your crucible with brass. After 10–30 minutes, add the pieces of brass to your crucible, handling them gently to avoid damaging the crucible. Waiting until the furnace is partially heated may help heat the brass rapidly, giving less time for the zinc in the alloy to separate and burn off.

Keep the furnace going until the brass is completely melted. The amount of time this takes will vary greatly with the strength of the furnace. If you have a pyrometer for measuring high temperature, keep in mind that most brass will be fully molten at about 1,700ºF (930ºC), but this can vary by about 50ºF (a difference of 27ºC) depending on the type of brass. If you do not have a pyrometer, move on to the next step once the metal is glowing orange to orange yellow, or when the color becomes almost invisible in daylight. Remember to avoid any smoke that emerges from the furnace, and to wear safety equipment while nearby. While heating metal slightly above the melting point makes it easier to pour, overheating can cause its own problems, such as oxidization. Judging when the metal is ready to pour becomes easier with practice.

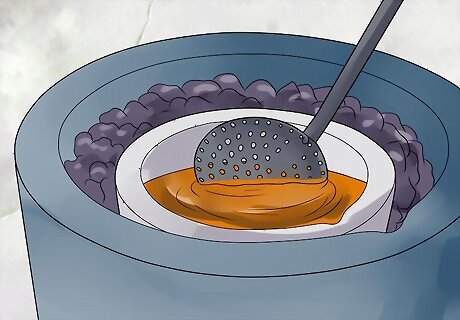

Skim the dross off the brass. Use your steel skimming spoon to remove the top layer of discolored or oxidized dross from the brass, and deposit this waste onto dry sand. This will also give you a sense of whether the brass is fully melted, but try not to stir the brass or extend the spoon deep into the metal. Stirring too much can mix air and gas into the metal, which can cause defects. Note that some other metals, such as aluminum, create gases on their own, and require stirring to release these.

Pour the molten brass into molds. Lift the crucible out of the furnace with steel tongs, and deposit it into the ring of the pouring shank. Use the shank and tongs to lift the crucible and pour it carefully into the molds. Some spill is likely to occur, which is why the molds are kept over dry sand to minimize spatter. You may now fill the crucible with more brass, or turn off your furnace and wait for everything to cool down. The furnace may take many hours to cool, but the ingots should be ready to handle well before that.

Comments

0 comment