views

X

Expert Source

Art FrickeHome Renovation & Repair Specialist

Expert Interview. 1 July 2020.

Powered mortar is simple to mix and has a consistent quality to it, but you could also make your own mortar out of cement to save on costs. After you make a bucket of thick but spreadable mortar, use it to install tiles over a wall or floor.

Using a Mortar Powder

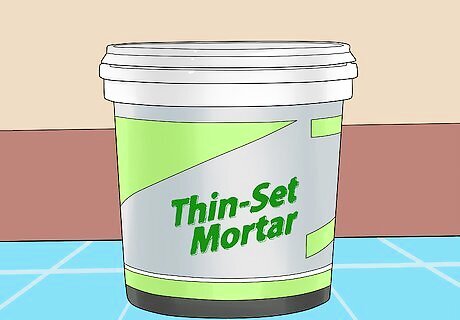

Choose a thinset powder to mix a more consistent mortar. Thinset mortar is made for use on tile to bond it to surfaces like cement and concrete. Most of it comes in a powder form that you mix with water to create a finished adhesive. When you buy a powdered mortar, you know you are getting a quality product that serves as a strong adhesive. Thinset mortar is also called thinset cement, dryset mortar, and drybond mortar, so keep in mind that they are all the same product. Thinset mortar is not the same as grout mortar or masonry cement. Most mortar gets stronger when you use more of it. Thinset mortar is strongest in thin layers, making it the best choice for tile. You could also get a pre-mixed thinset mortar that comes in a plastic tub. All you have to do is add water to activate it. It is easier to use and even more consistent than mortar made from powder, but it is more expensive.

Pour the water you need into a 5 US gal (19 L) plastic mixing bucket. On average, you need about 1.5 US gal (5.7 L) of water for a 50 lb (23 kg) bag of mortar. Adjust the amount according to how much mortar you plan on using. Then, add the water to the bucket first to reduce the amount of dust kicked up by the mortar when you add it. Check the mixing instructions on your bag of mortar before beginning. Not all mortar products are the same, so the manufacturer may recommend a different mixing ratio.

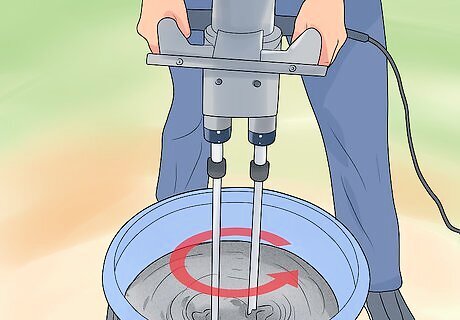

Add the mortar gradually to the bucket. Since mortar gets a little messy, put on a respirator mask before you begin mixing it. Also, wear safety glasses and latex gloves for additional protection. Pour the mortar into the water, swirling the mixture around with a trowel or a paddle mixer. Remember that you can always add more mortar at this point as needed to reach the proper consistency, so you don’t need to rush and dump it all in at the same time. To estimate how much mortar you need, multiply the length of the longest and shortest walls in the room together. Then, divide the number by 95 to figure out how many 50 lb (23 kg) bags of mortar to get. For example, if you have a 12 ft × 12 ft (3.7 m × 3.7 m) room, you need about 2 bags of mortar to cover the floor. Some of the powder turns into an irritating cloud of dust when you pour it into the bucket. To limit the dust, pour the mortar in as gradually as possible. Always wear a respirator mask and avoid adding the powder to an empty bucket.

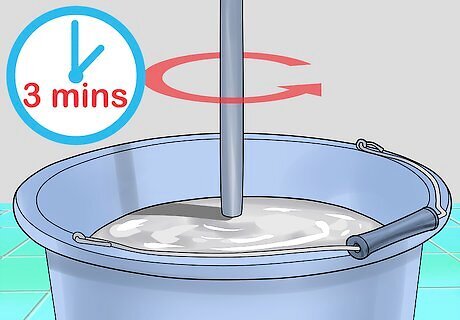

Mix the mortar for about 3 minutes until it reaches a thick consistency. Stir the mortar until it reaches the consistency of a thick peanut butter or toothpaste. To test the consistency, pull your mixer out of the mortar, creating a swirl. If the swirl stands up without disappearing, like a swirl on a meringue pie, the mortar is ready. If it isn’t at the consistency you need, add more water or powder to change it. For example, mix in more powder to thicken the mortar. Use water to thin it. Always mix the mortar a little more than you think you need to in order to blend the ingredients as thoroughly as possible. The exact mixing time can vary. You could even spend 5 to 10 minutes mixing to ensure the mortar reaches the right consistency.

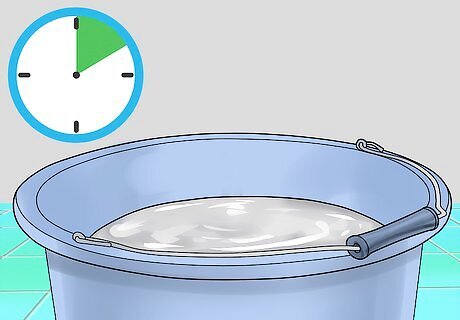

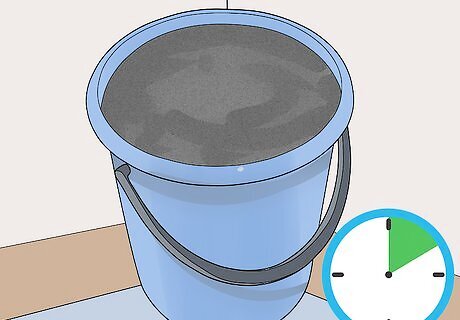

Let the mortar rest for 10 minutes to activate properly. This part of the process is called slaking. Rest the mix to ensure all of the powder moistens and becomes mortar. It also activates the additives that are important for bonding. If you don’t let the mortar rest, it stiffens up and doesn’t cure correctly. You then end up with loose tiles that don't stick to the mortar.

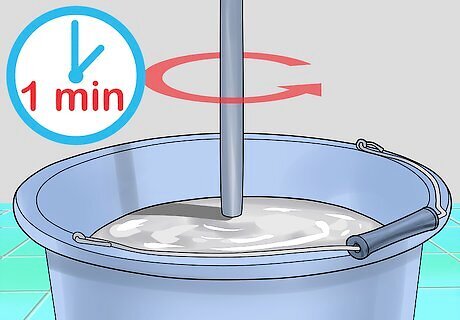

Stir the mortar again for 1 minute to finish it. Now that the mortar has activated, give it one final stir to distribute its additives evenly. Keep stirring it until it reaches the final consistency you need for your project. When the mortar is at the right consistency, it stands up when you work it into ridges with your trowel. Don’t add any water or powder at this point! Adding extra ingredients thins the mix out, creating a weaker adhesive.

Making Mortar from Scratch

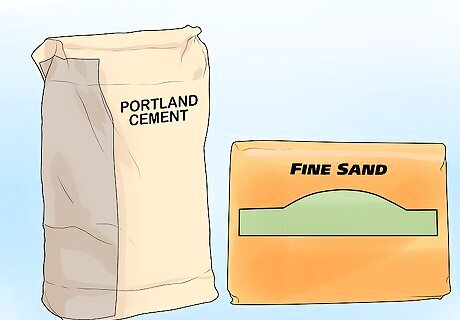

Create your own mortar out of cement and sand to save money. Portland cement is the basic component of any mortar mix. You also need a matching amount of fine sand without clay or stones in it and a liquid latex additive to strengthen the mix. These ingredients are all less expensive on their own than powdered or pre-mix thinset mortar, but they are tougher to mix to the correct consistency. The biggest issue with custom mortar comes when you mix multiple batches, since getting them all to the same consistency is tough to do without experience. If you’re new to working with mortar, start with a powder to ensure you get the right consistency you need for your project. Make your own mortar once you’re ready to experiment with combinations of cement and sand.

Sift sand through a ⁄4 in (0.64 cm) wire screen. Any sand you get likely includes tiny stones that have to be removed. To do this, get a piece of wire fencing with small openings. Set the fencing on top of a bucket or a plastic tarp, then pour the sand on top of it. Let the sand fall through the screen, leaving the stones on top of it. The stones cause the mortar to be rougher than normal. This isn’t a problem with thicker types of concrete, but it weakens thinset mortar.

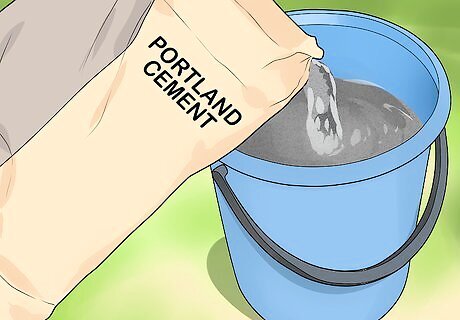

Pour Portland cement into a mixing bucket or a container. Cut open the cement bags you plan on using for the project. If you’re unsure about how much you need, start with a little bit first. Try using about 12.5 lb (5.7 kg) at first, for example, since you don’t need a thick layer of thinset mortar for tiles. You can always add more mortar to the mix as you go or make a second batch. To calculate how much cement you need, measure the length of the longest or shortest walls in the room. Multiply the lengths together, then divide the total by 95 to get an estimate of how many 50 lb (23 kg) bags of cement to use. Try to make only as much mortar as you can use within a few hours. Mortar dries out after that, becoming unusable.

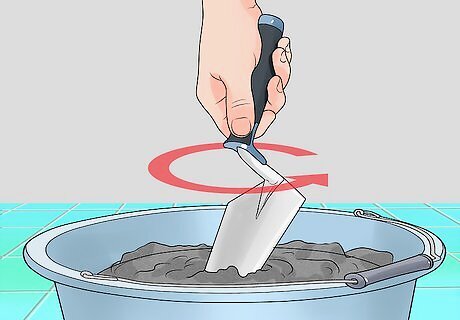

Stir a matching amount of sand into the cement with a trowel. Sand thickens mortar, so add it sparingly at first. Plan on using about twice as much sand as concrete, about 25 lb (11 kg) for a small batch. After adding the sand, tilt the bucket at about a 45-degree angle, then begin stirring the mixture with a trowel until it is well-combined. As you work, scrape sand and cement off the sides of the bucket to ensure it all gets mixed together. Put on a respirator mask, safety glasses, and gloves to protect yourself from dust and other irritants. If you don’t have a trowel handy, you could also use a paint mixer or mixing stick.

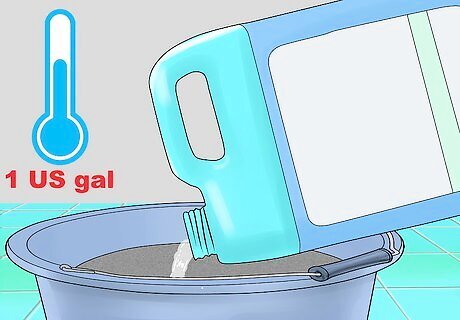

Add 1 US gal (3.8 L) of cold water to a separate mixing bucket. Fill the bucket with all the water you plan on using for the mortar mix. Start with a small amount to prevent the mortar from becoming too runny. This also leaves plenty of room in the bucket for the remaining ingredients you need. Remember that you can always add more water later to thin the mortar as needed. You can’t take out what you add to the mix. Once you become familiar with making mortar, you could try mixing it in bigger batches using more of each ingredient. However, smaller batches are easier to mix to a good quality at first.

Mix the sand and cement into the water using a paddle. Get a paddle mixer or a paddle you can plug into the end of an electric drill to make the mixing process easier. When you’re ready to begin, pour the cement mixture into the water to reduce the amount of dust that comes up. Then, stir the ingredients together until they look evenly distributed in the bucket. Start with the paddle on a low setting, about 300 rpm, to avoid splattering mortar everywhere. Stir the mixture together for at least 3 minutes to ensure everything gets mixed together. This also gives you an opportunity to determine the mortar’s consistency. You could stir the mortar with a trowel, but the mixing process takes longer. Expect to spend at least 5 to 10 minutes stirring it by hand.

Add more cement, sand, and water to change the mortar's consistency. The hardest part of making custom mortar is getting it to the correct consistency. Thinset mortar needs to have a thick, spreadable consistency similar to a thick batter, peanut butter, or toothpaste. Pour the additional components in gradually, stirring the mortar each time to test the consistency. Use more water to thin out the mixture. Add more sand and concrete to thicken it.

Let the mortar mixture rest for 10 minutes in a dark area. Take the bucket into a shaded area to prevent it from drying out before you have a chance to use it. Mortar dries very quickly, but it also weakens if you don’t let it rest. Set it aside so the mixture activates into a strong bonding adhesive. For example, set the bucket near a wall away from nearby windows. You could also put it under a shady tree or stick it in a closet.

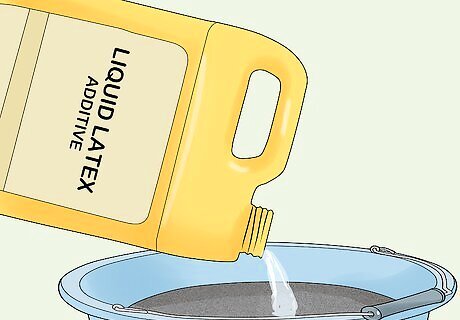

Pour a liquid latex additive into the mortar to strengthen it. The liquid latex is the secret ingredient that gives the mortar its strength. Without it, you get a stiff mixture that doesn’t stick to tile. For a 12.5 lb (5.7 kg) batch of mortar, stir in about 0.125 US gal (0.47 L) of the additive using a paddle mixer. Mix the mortar well so the additive gets evenly distributed throughout it. Mix in another 0.125 US gal (0.47 L) for every 12.5 lb (5.7 kg) of concrete you use. You could also mix in extra to thin out the mortar if it is still a little too thick.

Test the mixture after letting it rest for another 5 minutes. Give the additive some time to activate as it absorbs water. Then, pick up some of the mortar with a trowel. If the mortar looks stiff and hangs off the end of the trowel without falling, start laying tile. If it isn’t ready yet, add more of the additive, blend the mortar, then let it rest again. Another way to test the mortar is by picking up a little bit, but only when you’re wearing a latex glove for safety. If the mortar feels sticky and thick but pliable enough to spread with a trowel, you can use it for tile.

Comments

0 comment