views

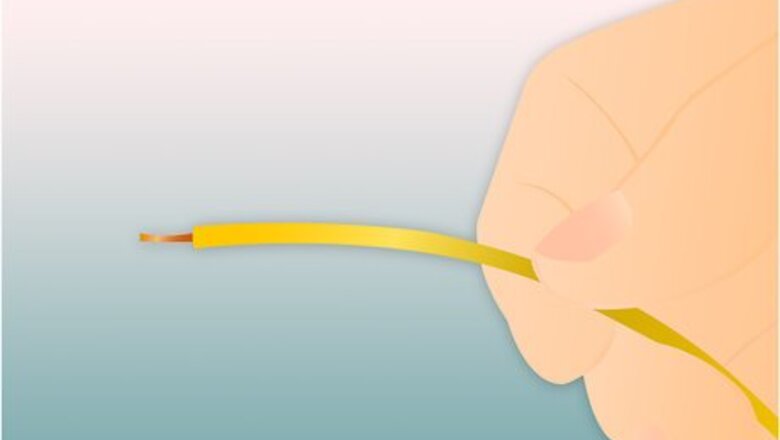

Strip the wire about 3/16".

Select the correctly sized seal and slip this over the wire's insulation. It should fit kind of snug on the wire so it will not try to slip when you crimp it.

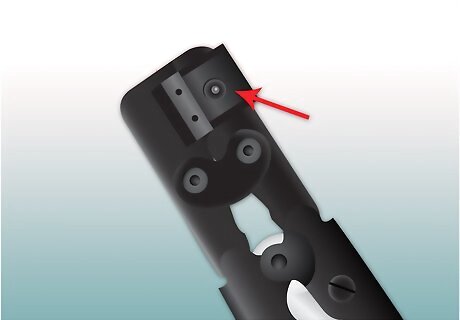

A high quality Weather Pack Crimping tool is very important for a good crimp. This tool is, as far as we can tell, 100% identical to the actual Delphi tool. In direct comparisons I can't tell a difference. Cheap tools just don't seem to cut it so I wouldn't scrimp here.

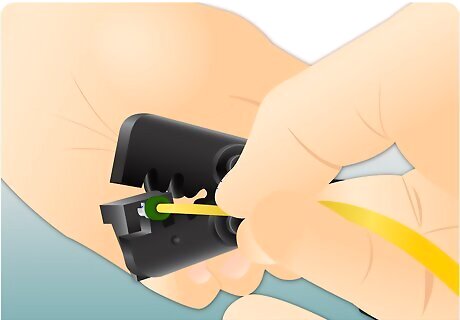

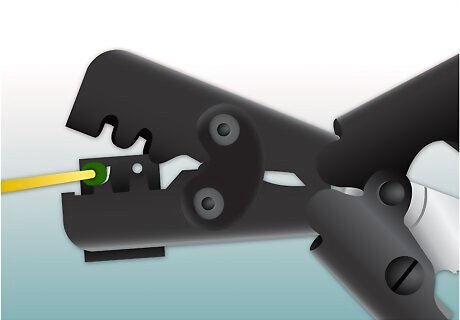

Notice this terminal positioning block on the back side of this crimper, that will be key to a perfect crimp. It's also a ratcheting style crimper which helps to make sure you crimp the terminal with the proper amount of force. Here's another look at the terminal positioning block from the other side of the WeatherPack Crimping Tool. You'll slip the terminals into the hole in this block (in the proper gauge slot), and it helps to maintain the terminal in the correct positioning for a perfect crimp.Assemble Weather Pack Connectors Step 4Bullet1.jpg Here an 18-20ga female terminal has been positioned in the tool.Assemble Weather Pack Connectors Step 4Bullet2.jpg

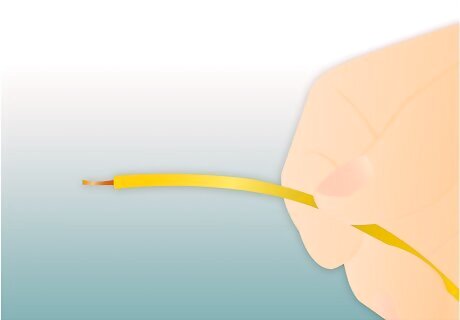

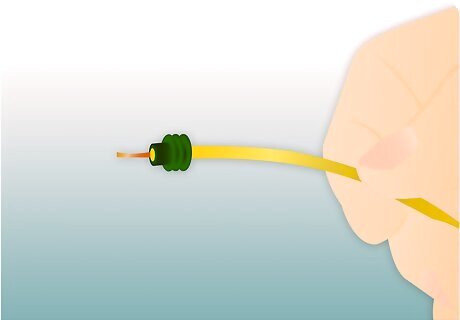

Slip the already stripped wire and seal assembly into the terminal. The smaller portion of the seal should be inside the tangs of the terminal. That way once crimped, the tangs grab the seal and hold it tightly.

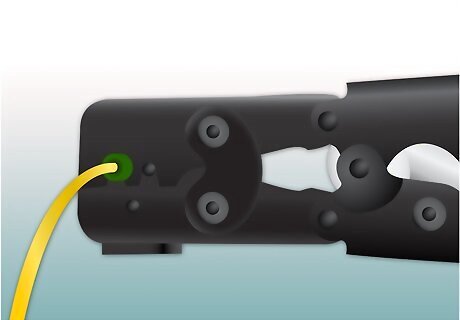

Squeeze the Weather Pack Connector tool's grip to crimp the terminal.

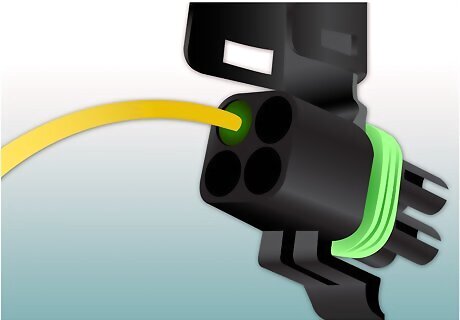

After the terminal has been crimped, the ratcheting mechanism of the crimping tool will release and allow the tool to open, releasing the crimped terminal/wire. Here's a view of a properly crimped terminal/seal/wire assembly.Assemble Weather Pack Connectors Step 7Bullet1.jpg This is a 4 pin Weather Pack Connector 'tower' housing. To help prevent confusion, female terminals are used with 'Tower housings' and male terminals are used with 'Shroud housings'. Crimping and assembly is the same no matter if you're using a tower or shroud, or a male/female terminal.Assemble Weather Pack Connectors Step 7Bullet2.jpg

Now you can poke the crimped terminal/wire/seal assembly into the back side of the WeatherPack housing.

Once you've inserted the terminal properly, you will feel it 'click' into place, and it will not pull back out easily due to the retainer tangs. To remove the terminal that this point you need a Weather Pack Removal tool (included in our larger kits) which makes it very easy to remove the terminals. In this example we've only inserting one crimped wire/terminal into the housing. The same process is used for the remaining wires/terminals. Once all of the wires/terminals are in place, snap the retaining cover over the rear of the housing. And here is your finished product.Assemble Weather Pack Connectors Step 9Bullet2.jpg Here is another view looking down into the housing allowing you to see the visible terminal.Assemble Weather Pack Connectors Step 9Bullet3.jpg Properly assembled, these Weather Pack Connectors will serve you well. They're manufactured for underhood automotive use, are chemical and weather resistant, and make a solid electrical connection. We use them all over the place, in race car engine harnesses, streetcar harnesses, adding an electronic box/fan/whatever that we want to be able to quickly disconnect for service/replacement/testing. For example here's an underhood shot of a 2009 Dodge Challenger Drag Pak Stock Eliminator car-- we used Weather Pack Connectors throughout this installation allowing for quick disconnect and/or removal of all components, even the entire engine harness can be disconnected in seconds using the two larger 22pin bulkhead Weather Pack Connectors you can see back on the passenger side of the firewall.

Comments

0 comment