views

Removing Obstructions

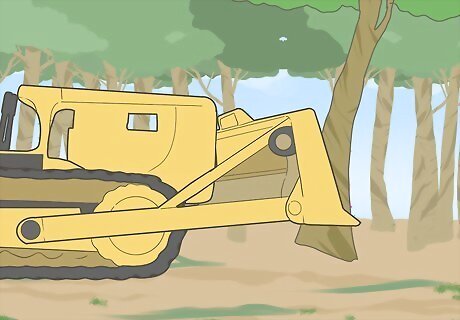

Drive head-on into trees to knock them over. Elevate the bulldozer’s blade so that its upper edge is positioned right around the tree’s midpoint, then push forward. If you encounter resistance from the roots, back up and lower the blade to get up under the biggest clump. You should then be able to push it the rest of the way down with little difficulty. Some bigger bulldozers come with attachments known as “tree pushers” or “tree spears” which make toppling towering, deeply-rooted trees almost effortless. On most newer dozers, you’ll find the joystick that controls the height and angle of the blade on the console beside the operator’s seat.Tip: For tall, stout trees measuring 6–12 inches (15–30 cm) or more in diameter, raise the blade to its full height to increase your leverage.

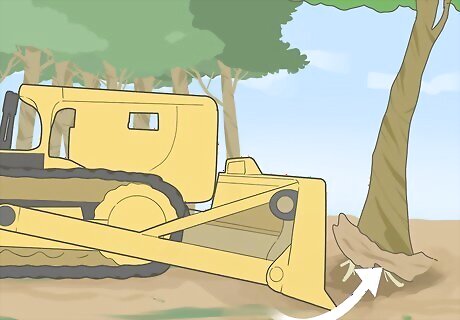

Set the blade level with the ground to uproot stumps. Bring the blade down until its lower edge is flush with the bottom of the stump and rolling over it. The sharp cutting strip at the bottom of the main blade will sever the stump’s connection with the earth while the curved blade itself “scoops” it up from underneath, tearing it free from the roots in the process. Small dozers may lack the horsepower needed to easily dislodge sizable stumps. If you have numerous stumps covering your work site, it’s a good idea to invest in a larger machine, if at all possible. You stand to save both time and energy by “grubbing” stumps with a bulldozer in this way rather than breaking them up by hand or with smaller equipment.

Blast monstrous stumps with explosives to reduce equipment costs. Dig one or more holes in the soil off to one side of the stump deep enough to insert a pre-measured explosive charge. Plant the charge beneath the stump and give yourself plenty of time to get a safe distance away and take cover before setting it off. A carefully controlled blast will “crack” the stump without littering your work site with debris or leaving a crater for you to fill in later. Most clearing blasts are carried out using ANFO (short for “ammonium nitrate/fuel oil”), an inexpensive and commonly-used industrial explosive readily available to those with the proper permits. If your work site is overrun with the remains of giant trees (and if your local ordinances allow it), it may be cheaper and speedier to blow them to pieces than to dig them out one-by-one with a dozer that you’re paying for by the hour. Blasting may not be a very practical solution for all land owners, as it requires special training and legal documentation and cannot be performed in areas containing underground utility lines, wells, sunken foundations, or nearby structures.

Lower the blade below surface level to dig out shallow roots and debris. When dealing with below-ground obstructions, you’ll need to get your blade as far down as it will go. As you glide over the terrain, the cutting strip or teeth along the bottom of the blade will sink deep into the soil, churning up anything that happens to be buried there. Even so, it may be necessary to make several passes in order to clear out overgrown areas completely. If you’re operating a dozer that has a blade with an adjustable pitch, angling the blade forward can help put more of the cutting strip into contact with the earth. Ideally, you’ll want to scour the soil to a depth of 1–2 feet (0.30–0.61 m), unless you’ll be using your site for agricultural purposes, in which case you should aim for a maximum depth of 15 centimetres (5.9 in). A root rake can be a worthwhile investment if you find yourself up against old or extensive root systems that run deep. This attachment, which fits right over the dozer’s blade, features a row of long, curved teeth that will extend your reach and attack stubborn roots from multiple points at once.

Gather brush and debris into neat piles where they can be disposed of easily. After clearing a given area, push the clutter you’ve generated to one edge or corner of your work site to get it out of the way. Do your best to separate your piles into natural and non-natural materials. That way, you’ll know right away what you can burn and what you’ll need to cart off. The number of waste piles you produce will depend partly on how much material you have to clear and partly on the size of your work site. For smaller plots of land, you might be able to get by with one or two piles, whereas you’ll likely need more if you’re covering a lot of ground. Take the time to sift through your respective piles and remove items that don’t belong—it can be hazardous to both your individual health and that of the environment to burn things like plastics or treated metals.Warning: Items like tires, automobile batteries, fuel containers, and buried electrical components often require special disposal methods. If you’re not sure what to do with something you’ve uncovered, call the Department of Environmental Protection for your state or territory to get an expert recommendation.

Burn brush piles while you finish clearing your work site to save time. It’s easier to incinerate mounds of splintered stumps, loose branches, vines, and dead wood than it is to transport them somewhere else. And it’s a better use of your time to do it as you go than to wait until after you’re done with your project. If possible, have one or more assistants on standby to get the fire started while you or your operator focus on maneuvering the bulldozer. Make sure each of your burn piles is surrounded by a gap of at least 15–20 feet (4.6–6.1 m) to keep the blaze under control and prevent it from spreading accidentally. Load the waste that should’t be burnt into a dump truck with the dozer and dispose of it properly.

Turning and Reshaping the Ground

Use your dozer's ripper to bust up pavement, bedrock, and compacted earth. Use the hand controls for the machine you’re working with to plunge the shank below the surface of the ground as you drag it behind you. Doing so will cut clean through solid materials and loosen dense patches of dirt that might otherwise be tough to get through with the blade. The ripper is the spike-like piercing device situated on the back of some bulldozers. It’s function is to “rip” up hard surfaces prior to routine excavation. Single-shank rippers are typically used for serious multi-directional surface destruction, while multi-shank rippers are better suited for raking and turning.Warning: Always drive in a straight line while ripping—attempting to turn with the shank underground could result in damage to your dozer. If you need to change direction, raise the ripper until it’s clear of the surface, back up, and start over at a slightly different angle.

Relocate excess soil to build up ditches, gulches, and other low spots. Tilt your blade forward to put the cutting strip or row of bottom teeth at an angle with the ground. Then, ease forward to scrape up soil from the surface of your work site and push it wherever you need it to go. This is a much faster and less taxing way to move massive amounts of soil than attempting to use tarps, wheelbarrows, trucks, trailers, or other small equipment. You’ll be able to move more soil at a time using a dozer with a curved universal or semi-universal blade, but a basic straight blade will also get the job done nicely. You can also shift large quantities of earth around as needed to fill in ponds and wet lowland areas. Don’t forget to mix some gravel or another drainage-promoting substrate material into the soil by hand later on.

Go over your cleared site in overlapping strips to get it nice and level. Lower the blade until its bottom edge is roughly even with the surface of the soil and cruise along slowly. For best results, roll back and forth over the land in alternating directions, making sure the swaths leveled on each pass are no further apart than the width of the blade. Alternatively, you can work your way outward from the approximate center of your work site. If your bulldozer came equipped with an advanced grade control system, take advantage of it. Otherwise, you may end up losing valuable time going back to correct your work. Proper grading is a must if you intend to use your site to install structures or features that must sit perfectly level.

Comb the land in at least two different directions to be thorough. Making multiple passes over your work site in different directions will do a better job of digging up complex root systems, smoothing out uneven terrain, and separating tightly-packed soil as you come to it. Not only that, but you’ll also cut down on your overall project time by not rolling aimlessly from place to place. For example, you might start by running the dozer over your site from east to west, then reset and repeat the process going north to south.

Comments

0 comment