views

X

Research source

Resizing Tin Siding

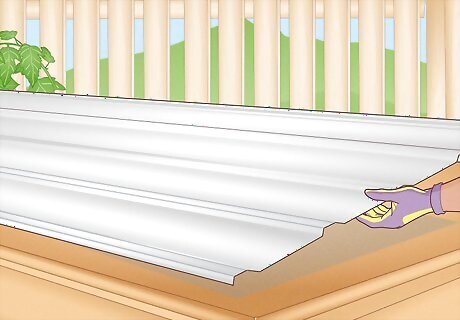

Place your siding on a flat work table. Set up a flat work area that is large enough to set your siding down flat. For best results, use a work table that is about waist height for you.

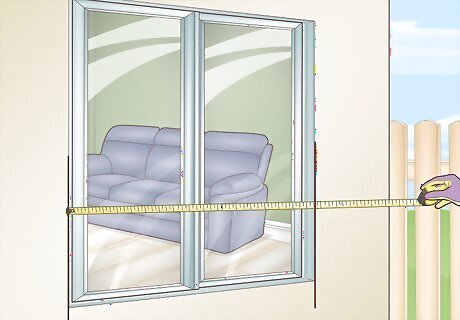

Determine the locations of obstructions. Each panel of tin siding will be hung vertically. Ideally, you will select panels that match the height and width of your building. However, you will need to trim the panels that hang over doors, windows, or other obstructions. Follow a blueprint, or measure these obstructions manually. Write down your measurements. Standard lengths for tin panels are 8 feet (240 cm), 10 feet (300 cm), and 12 feet (370 cm). The most common widths are 36 inches (91 cm) and 26 inches (66 cm).

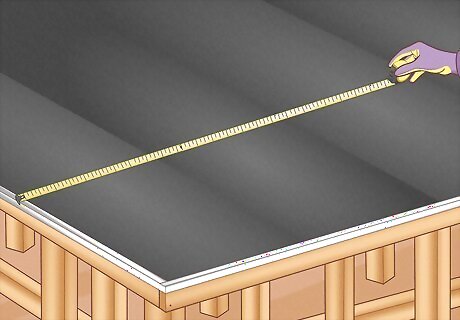

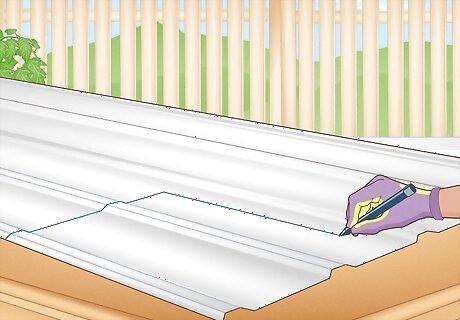

Measure your tin panels. Use a tape measure to mark the places you will need to trim your tin panels. Measure each intended cut in 3 different spots. Make small marks on the siding with a permanent marker. Use a carpenter's square or flat piece of wood to make a straight line.

Prop your siding up on a 2 x 4 (45 x 90 mm). You need to create a small window of space under your siding in order to cut a straight line. You can do this by sliding a 2 x 4 (also called a 45 x 90 mm) underneath your siding panel. Position the wood so that it is parallel to where you plan to cut, about 2 inches (5.1 cm) away from your marks.

Choose metal shears for the safest tool. Secure the siding with your non-dominant hand. Carefully slide your sheet metal shears across the siding, so that it intersects the measurements you made. Tin siding is not perfectly flat. Try to maintain a straight line as you move across ridges in the siding.

Use a circular saw to make quicker cuts. If you have a circular saw at home, you can use this instead of sheet metal shears, following the same method. First, attach a specialty blade for cutting tin (available at most hardware stores), then carefully run the saw across your siding. This will leave a jagged edge. Run a deburring tool over the jagged edge to help smooth it out. Using a circular saw on tin siding can be very dangerous. Do not attempt this unless you have experience with circular saws.

Trimming Tin Roofing

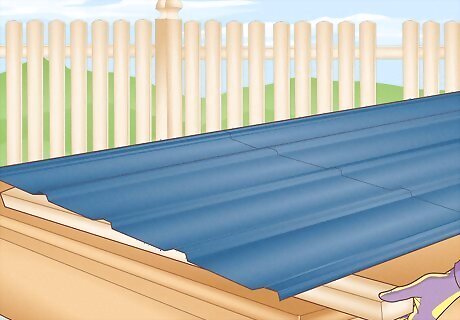

Determine how many sheets of corrugating roofing you need. Measure your roof and figure out how many sheets of tin to buy. Standard lengths for tin roofing are 8 feet (240 cm), 10 feet (300 cm), and 12 feet (370 cm). The most common widths are 36 inches (91 cm) and 26 inches (66 cm), but other possibilities include 24 inches (61 cm) and 39 inches (99 cm). The width of tin roofing is measured straight across the top of the sheet. It does not consider the peaks and valleys of the corrugated material. Remember that each sheet will need to overlap by several inches.

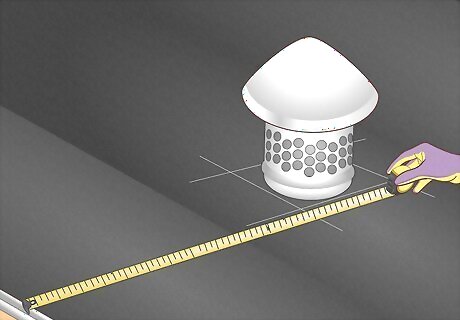

Determine the location of obstructions. If you choose the right size roofing, you should only need to cut the material to make space for chimneys, vents, and any other obstructions. Unless you have a blueprint for your house, someone will need to climb onto the roof and physically measure these items. Ask a friend to hold your ladder. Stay close to the roof when moving around. Avoid doing this during bad weather, or on a very windy day. Write down these measurements right away, so you won't forget.

Place the tin roofing on a flat work table. After you have the measurements for any obstructions, lay 1 sheet of tin roofing down on a flat worktable that is large enough to accommodate it. Use care when handling the tin. Tin roofing is very flexible, and it can be easily damaged.

Use a marker to label your tin roofing. Label the location of chimneys, vents, and any other obstructions directly on the tin. Use a permanent marker and either a 2 x 4 (45 x 90 mm) or a carpenter’s square to draw straight lines. Draw these lines on both sides of the tin to help ensure straight cuts.

Use tin snips to work carefully. Tin snips are a good choice because they are designed for cutting soft metals. With tin snips, you will move slowly, so you are unlikely to make mistakes. Stabilize the tin roofing with your non-dominant hand. Place the tin snips around the bit of tin you want to cut, and then squeeze down firmly. Move forward, and repeat. Right-hand tin snips can be used to cut tin when the “waste tin” (the tin you won’t be using) will be on the right side of the cutting line. Right-hand snips are also used to make a curve that runs counterclockwise. Left-hand tin snips are used when the waste tin is on the left side of the cut line. Left-hand snips are also used to makes curves that run clockwise. Center snips (also called straight cut tin snips) can be used to make straight cuts. Center snips cannot be used for curves.

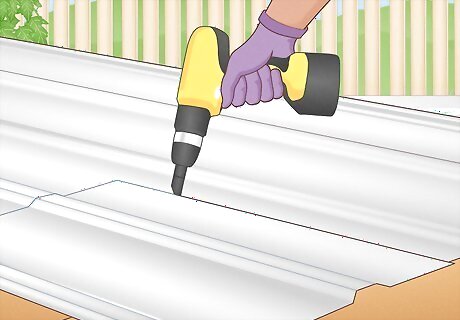

Cut with nibblers to accomplish the job quickly. Nibblers are special attachments for electric drills. Nibblers are great for cutting both curves and straight lines in tin roofing. They are especially useful for cutting around objects like vent pipes. Stabilize the tin with your non-dominant hand. Carefully move your nibbler across the tin.

Avoid using a circular saw. A circular saw can be used to cut tin roofing, but this is not recommended unless you are extremely experienced with using a circular saw. It can be very easy to make jagged cuts, damage the roofing, or get injured. If you do use a circular saw, you need to use specialty blades intended for use on tin roofing. The only real benefit to using a circular saw is that you may already have one. Instead of purchasing new tools, you would only need a new blade.

Comments

0 comment