views

Repairing Small Pieces with Glue

Buy a tube of high-strength plastic glue. If you’re attempting to fix a chipped edge or reattach part of a larger object, a strong adhesive may be all you need. Plastic glues are specially formulated to create bonds between plastic surfaces on a molecular level. Look for a product that’s designed for use with the type of plastic you’re repairing. Most standard super glues can also be applied to plastics with good results. You’ll find a wide selection of plastic glues, super glues, and similar craft adhesives at your local hardware store or home improvement center. Be sure to pick up enough glue to tackle your project without running out.

Spread the glue over the edges of the broken piece. To ensure a secure hold, dab the adhesive everywhere that it will connect with the larger object. Hold the tube in your dominant hand and squeeze gently to release a little bit of glue at a time. That way, you won’t have to worry about accidentally using too much or making a goopy mess of your work area. Wear rubber gloves when working with plastic glue to prevent the adhesive from getting on your skin.

Press the plastic piece into place. Line up the edges carefully—plastic glues dry quickly, so you may only get one shot. Once the piece is in position, apply constant pressure for 30 seconds to a minute. This will prevent it from slipping while the glue begins to set. It may help to tape the broken piece down or set a weighted object on top of it to hold it steady. A C-clamp can come in handy for holding together oddly-shaped items.

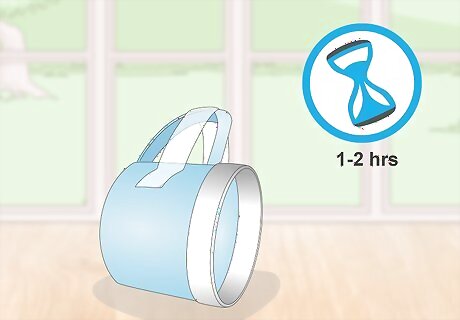

Allow the glue to cure. Different types of glue have different drying times. As a general rule, however, you’ll want to wait at least 1-2 hours before handling the newly-repaired item. Otherwise, there’s a chance that the broken piece will come loose and you’ll be right back where you started. Some types of glue may take up to 24 hours to cure completely. Follow the drying instructions outlined on the product’s packaging to see what additional drying tips the manufacturer recommends.

Fusing Plastics with a Soldering Iron

Glue the broken piece back into place. Start by reconnecting the separated surfaces and anchoring them with a powerful plastic adhesive. You’ll need to have both hands free to safely operate the tools you’ll be using to seal up the damage. Use just enough glue to hold the pieces together. It’s possible for the heat from the soldering iron to react with certain types of adhesive and cause discoloration. When you’re dealing with a crack, split, or clean break, melting down the plastic may be the only way to rejoin it.

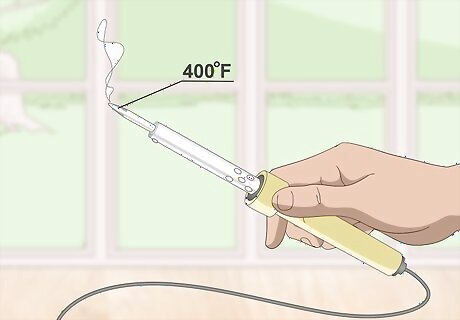

Heat up your soldering iron. Switch on the soldering iron and set it to the lowest temperature setting. You can begin getting your other components ready while the heating element warms the iron. This process may take several minutes. Don’t set your soldering iron higher than about 400–500 °F (204–260 °C). Fusing plastics doesn’t require nearly as much heat as fusing metals. Before you get started, clean the tip of the iron with a damp sponge to remove any residue from past projects.

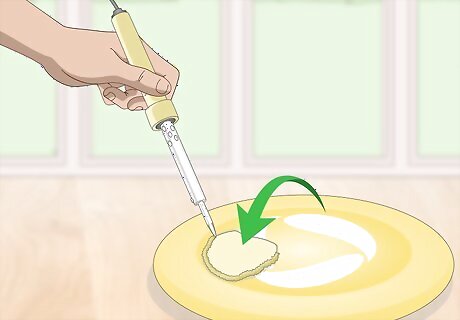

Use the soldering iron to melt the edges of the plastic. Rake the tip of the iron lightly over the joint where the two surfaces connect. The intense heat will instantly liquefy the soft plastic on either side, which will then merge together and reharden. The result is a connection that's much more durable than glue. Whenever possible, solder the pieces together along the backside so that the resulting seam will be less visible from the front. For your own safety, always don protective eyewear while operating a soldering iron. It’s also a good idea to wear a respirator or breathing mask and work in a well-ventilated area to avoid inhaling noxious fumes from the plastic.

Patch large holes with scrap plastic. If there’s a whole section missing from the item you’re trying to repair, see if you can dig up a replacement piece with a similar color, texture, and thickness. You’ll fuse the patch the same way you would a normal crack—run the tip of the soldering iron along the edges of the new piece until it melts into the larger surface. Ideally, the scrap piece should be the same type of plastic as the rest of the item. However, you should be able to fuse mismatched plastics successfully in most cases.

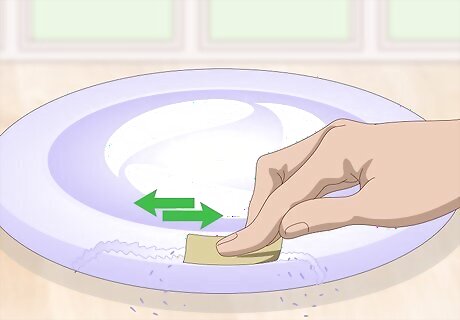

Sand the resulting seam to blend it. Go over the edge where the two pieces connect with a square of high-grit sandpaper (around 120-grit) until the most obvious imperfections have disappeared. When you’re done, wipe the item with a damp cloth to remove any dust generated by sanding. For an even smoother finish, use basic sandpaper to wear away larger inconsistencies like bumps and ridges, then switch to an ultra-fine variety (300-grit or higher) to even out the surface.

Solvent Welding Plastics with Acetone

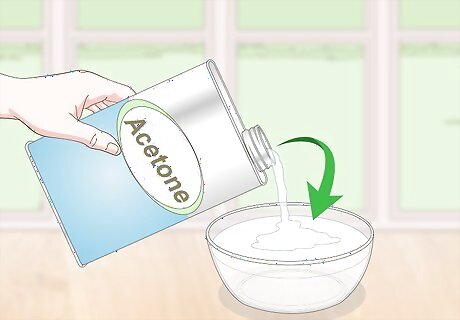

Fill a glass container with acetone. Set out a drinking glass, jar, or deep bowl with a large opening and pour in 3–4 inches (7.6–10.2 cm) of pure acetone. The container needs to be full enough to completely submerge multiple pieces of plastic. Choose a container that you don’t mind ruining in case you have trouble removing every last trace of plastic when your project is finished. It’s critical that whatever container you use be made of a material like glass or ceramic. You want it to dissolve the plastic you’ll be using for, not the cup that’s holding it. Acetone is a hazardous liquid that gives off powerful fumes, so be sure to work somewhere with good ventilation.

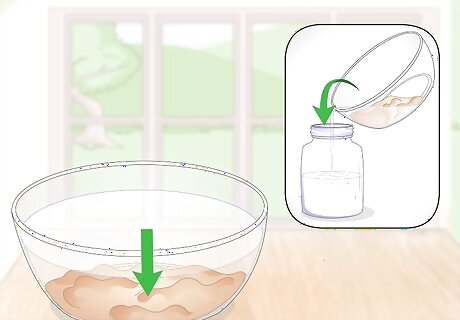

Place a few pieces of scrap plastic into the acetone. Stir the pieces with a toothpick to help them settle. The should be totally immersed at the bottom of the container. If necessary, add another splash of acetone to cover the tops of pieces with irregular dimensions. For a more natural looking repair job, try to find plastic in the same color as the item you're repairing. Avoid touching the acetone. It can cause mild irritation if it comes into contact with your skin.

Leave the plastic to dissolve overnight. As it soaks in the acetone, it will slowly break down to form a thick, goopy slurry. The exact amount of time this takes will vary depending on the type of plastic you’re working with and how much you’re melting down. Play it safe and let it sit for at least 8-12 hours. Cutting or breaking the plastic into smaller pieces may help speed things along. The more surface area it has, the faster the acetone will act on it. The slurry should have a smooth, creamy consistency and be free of lumps or chunks before you attempt to use it to weld other pieces together.

Once the heavier plastic has dissolved entirely, it will separate from the acetone and sink to the bottom of the container. Do not dispose of the excess acetone in a sink or toilet bowl, it must be taken to a hazardous chemical disposal site. Put the excess acetone in a glass jar with a tightly sealing cap and dispose of it at an approved hazardous chemical disposal site. Drain the liquid into a glass jar so that only the plastic slurry remains. You’ll use this as a filler to make your repairs. It’s okay if there are traces amounts of acetone left in the container. It will quickly evaporate on its own.

Brush the slurry into the damaged area. Dip a thin paintbrush or cotton swab into the liquefied plastic and dab it into the space between the two broken pieces. Try to work it as deep into the joint as possible. Continue dipping and brushing until you’ve filled in all cracks and gaps. If possible, apply the slurry to the back or underside of the piece so it won’t be as noticeable. Use as much of the plastic as you need to successfully seal up the damaged area (you’ll probably end up with quite a bit left over).

Give the plastic time to harden. Within minutes, the last traces of acetone will vaporize and the slurry will form a chemical bond with the surrounding plastic. Avoid disturbing the conjoined pieces in the meantime. Once the new plastic has had time to solidify, the item will be almost as good as new. The new joint will be about 95% as strong as the original plastic.

Comments

0 comment