views

Doing a Visual Inspection

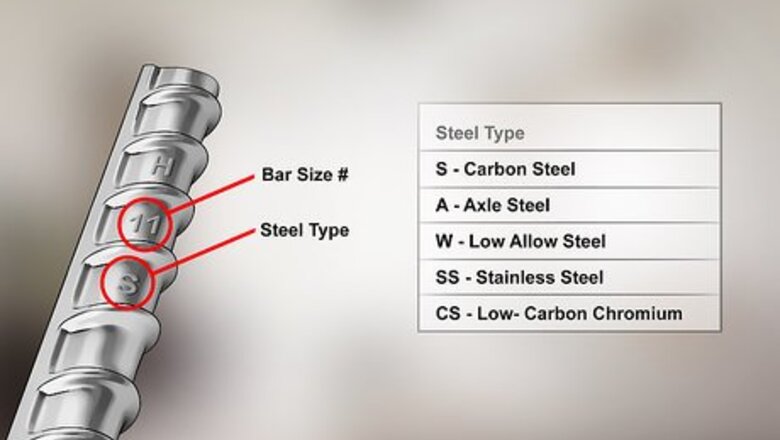

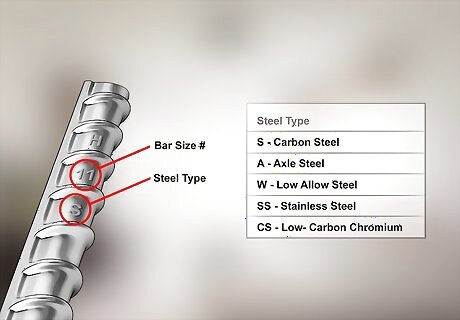

Check the metal for a number label. Inspect the surface of the metal first. If the metal has a number code printed on it, that may mean it is steel. This code may also be printed on the container or wrapping that protects the steel during shipping. If you don’t have that available, you will have to identify the metal through other means. One code system is the AES system. It’s a 4-digit code where the first 2 numbers indicate the type of steel. Search online to find an identification chart that explains what these numbers mean. The ASTM system is used on rebar. The first number in the code represents the size of the bar, while the letter under it indicates the type of steel.

Look for metal that is dark brown, shiny silver, or red with rust. Steel comes in a small range of colors, but you can still get a sense of what metal you have by looking at it. Carbon steel, used in pipes and buildings, is a dark brown color. Stainless steel, used in kitchens, is silver and shiny. In addition, reddish rust spots are an indication that the metal is steel. Stainless steel is a hard metal that typically won't get corroded or damaged. Metal that has a red or yellow tint is copper or brass, not steel. Copper may also turn green as it ages.

Chip the metal to look for a silver coloring inside. Before attempting a chip test, look for any fractures. These spots usually give you a view of the inside of the metal. Otherwise, use a hammer and chisel to break off a small piece. Steel’s inner portion is always bright gray. Hold the metal in place with clamps or vice grips before attempting to chip it.

Testing Other Characteristics

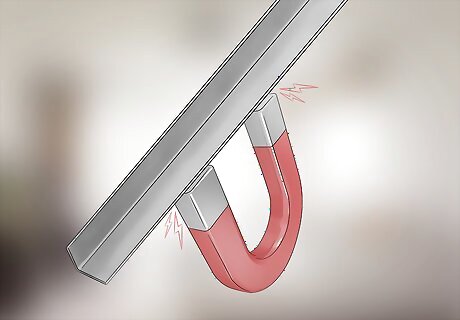

Make sure the metal is magnetic. If you are still uncertain, press a small magnet against the metal. Steel is generally magnetic because it is made of iron. Most other common metals, including aluminum, aren't magnetic. If the magnet sticks, the metal is most likely steel. Other magnetic metals are either rare or not used in pure forms. Cobalt and nickel, for example, are often components in steel. Some stainless steel is not magnetic. When nickel is added during manufacturing, the magnetism fades. Identify this metal by color, by weight, or by trying another test.

Look for a heavier metal rather than a lighter one. Aluminum and stainless steel are both shiny and silver-colored, so they look similar. Distinguish between them by handling the metal. Stainless steel feels much heavier than aluminum. Steel feels stronger, more solid, and less prone to breaking in your hands. To get used to the differences between these metals, compare household objects. For example, an aluminum can feels much different than a steel cup or utensil.

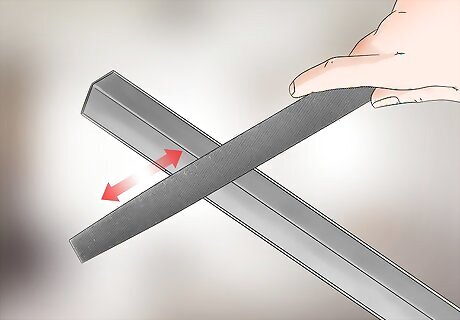

Test the hardness by filing the metal. Use a metal file to perform a file test. Lay the metal on a flat surface and rub the file against 1 end. Steel is a relatively hard metal, so filing off fragments should take some work. Depending on the file’s hardness, you may not even be able to wear off any of the metal this way. Look up the Moh’s scale for metals to compare hardness ratings. In contrast, lead, aluminum, silver, and many other metals are softer than steel. Wearing them down with the file is easier. Hardened steel, which has a medium to high carbon content, is stronger than all but a few metals. Most metal files won’t affect it.

Performing a Spark Test

Wear goggles and other safety gear. Take safety precautions before using a grinding wheel. Polycarbonate safety goggles protect your eyes from stray sparks and metal fragments. Also put on ear muffs to block out the machine’s noise and a respirator to avoid breathing in dust. Steel-toed boots are also a good idea. Wear these in case you drop a heavy piece of metal.

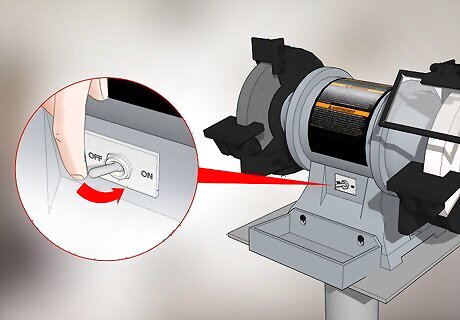

Turn on a bench grinder. To test the metal, you need some sort of spinning wheel. The faster it rotates, the more sparks it will produce. Get a bench grinder or handheld grinder with a 24-grit carborundum wheel and wait for it to spin up to speed.

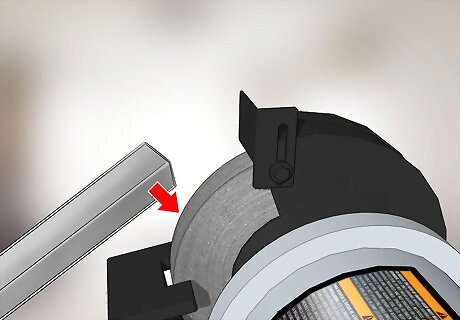

Hold the metal flat when pressing it against the wheel. Hold the ends of the metal in your hands directly in front of you. Keep a firm grip on the metal as you lower it onto the wheel. The contact produces sparks, which you should be able to see without moving your head. Adjust the metal’s position until you get a clear view of the spark pattern.

Note if the sparks branch out in a pattern. Maintain a light amount of pressure on the metal as you watch the sparks. Steel produces sparks that branch out into about 5 yellow streaks. All the streaks are different lengths. The ends of the sparks fan out into tiny branches or “leaves,” like on a tree. Search online for a visual aid by searching for the steel spark test. Both wrought iron and stainless steel produce long, even yellow streaks. The leaves on the end are smaller in stainless steel sparks. Steel made with less carbon produces yellow sparks with different lengths. The leaves on the end fan out more with a lot of extra little branches. Steel with high amounts of carbon produce sparks that begin spreading out near the grinding wheel. The sparks are duller or even red and fan out less at the end. Some metals, including nickel and aluminum, produce few or no sparks.

Comments

0 comment