views

Ordering a Bay Window and Removing the Old Window

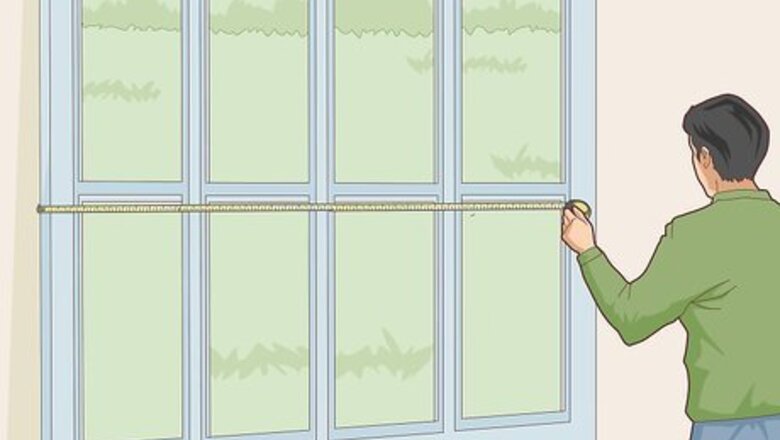

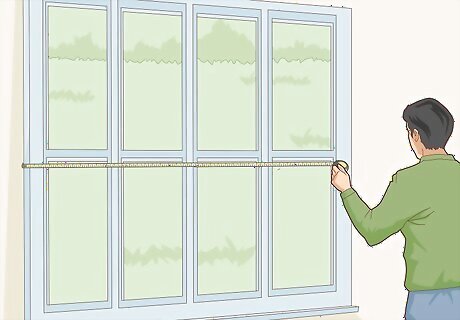

Hire a window manufacturer to measure the window or opening. Get quotes from local window manufacturers that make bay windows to explore your options. Once you find a contractor you’re interested in working with, have them come out to inspect the opening or window you’re looking to replace. They will take measurements and walk you through your options based on the shape of your window and the surrounding wall.Tip: There’s a lot of nuance to the measuring. It isn’t just about the rectangular shape of your window—a good bay window measurement requires a complex understanding of the shape of the studs in the wall, the clearance under and over the window for anchors, and the load-bearing capacity of the frame itself. It’s typically free to have a contractor come out, take measurements, and inspect the frame to make sure it can hold a bay window. This isn’t realistically something you can do yourself, though.

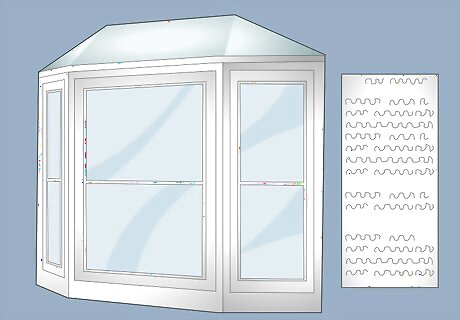

Order a bay window in a style you like to match your home. Once your window is sized, sit down with the contractor to see the bay windows they offer. Choose a bay window that matches the style of your home. Typically, vinyl bay windows are cheaper while wood windows tend to be a little more expensive. Order a bay window you like and wait for it to be delivered. The cost of a bay window depends on the size and style you’re going for. It will likely cost $800-3,000 depending on the size and material. Bay windows come preassembled, but the siding, top and bottom panels, and roof cab are occasionally not included. If the contractor offers to cut these pieces to size for an additional fee, consider taking them up on your offer. It’ll save you a lot of work if you can get these pieces precut. The cables and hanging materials for the roof will all come with the window. The same is true for the clamps you need to hang the cables that hold your roof up.

Remove the old window if there’s already a window in the opening. Put on some gloves, protective eyewear, and a dust mask. Press the tabs in on the top of the glass pane and lower the pane towards you. Pull the window out of the frame once you’re holding it perpendicular to the frame. Some window panes have a little tab that flips up instead of sliding into the middle of the window.

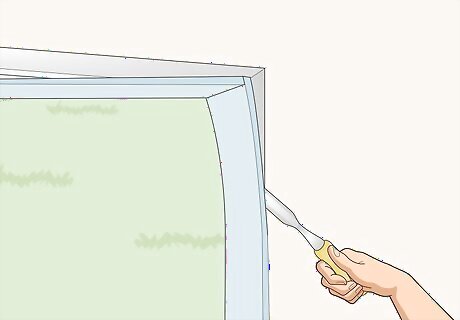

Peel out the old frame with a chisel and pry the old frame out. Grab a chisel and slide it underneath the first bit of trim. Press on the chisel to pry it out. Repeat this process for each length of wood covering the frame. Peel out the trim on both the inside and outside of the window to expose the frame itself. Use your chisel, a rubber mallet, and a crowbar to peel the frame out of the wall. This may take 30-45 minutes depending on how strong the window frame is here. Be ready to make a bit of a mess and put some effort in!

Take out the window sills and nails to make space for the new window. Pry out the base of the window the same way you removed the rest of the window frame. This may require two people with chisels depending on how strong the window sill is. Then, use a nail remover to rip out any nails sticking out of the frame that used to hold the sill or siding. You should now have the wood frame surrounding your window, entirely exposed. Feel free to take a 10- to 20-minute break after you’re done here. Grab some water and a snack. Removing an old window frame can be quite exhausting! Don’t remove any nails holding the joists in place. Any nails that are flush in the wood joists are holding them in place and must stay in place.

Levelling the Frame and Hanging the Window

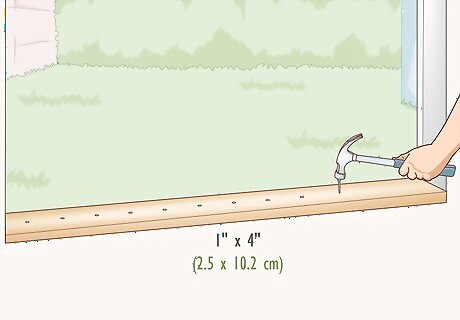

Install a flat 1 by 4 in (2.5 by 10.2 cm) wood board on the bottom of the opening. Measure the distance from one joist to another along the base of the opening. Use a circular saw to cut a 1 by 4 in (2.5 by 10.2 cm) wood board to size. Lay it down in the opening and use a level to make sure this board is perfectly even. If it isn’t, prop it up on both sides with shims until it’s level and nail it into the joist underneath. Place one nail every 4–5 inches (10–13 cm) to keep the board from coming loose. If you use shims and some of them are sticking out at the sides, score the excess wood with a utility knife and break them off with a rubber mallet. You don’t have to hit hard here—just tap the wood and it should snap off.

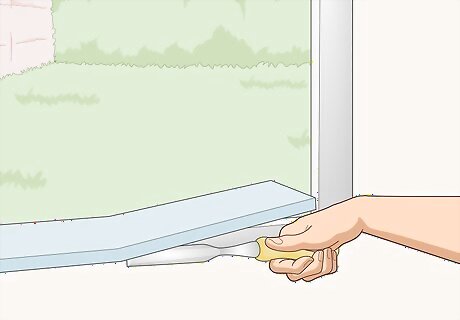

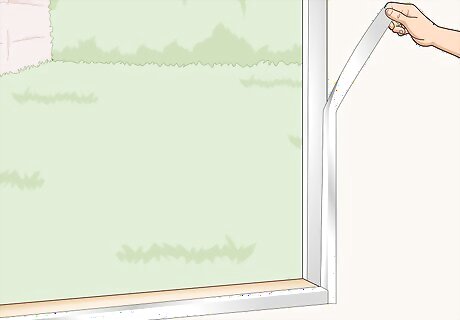

Apply flashing tape around the edges of the opening to keep air and moisture out. Grab a roll of aluminum flashing tape. Peel off the tape and lay it down around your entire frame. Cover the seam where the exterior edge of the opening leads into the exterior wall at a 90-degree angle. Use multiple strips of tape as needed and smooth all of it down with the edge of a putty knife. The flashing tape functions kind of like a moisture barrier between the wood frame and the window. If any moisture gets in between the window and the surrounding joists, you window may sag or become drafty.

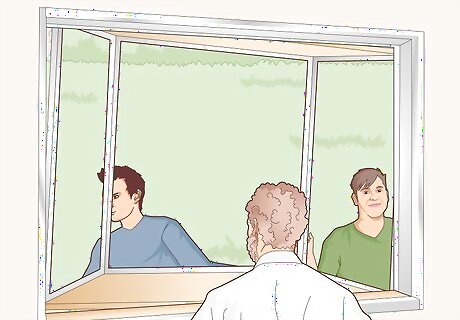

Enlist 2-3 friends to help hoist the window into the opening of the frame. The bay window will likely weigh 50–150 pounds (23–68 kg). Enlist a few friends or helpers to hoist the bay window into the opening in your wall. Lift the window up by the angular sides to balance it and keep it level. Stand on the inside of the building and line the edges up at the top and the bottom of the window. Slide the window into the frame so the bottom of the window sits on top of the wood board you drilled into the base of the frame.Tip: This can be a pretty delicate process. Just make sure that your helpers have a good grip on the window while you’re lining it up from the inside. Double-check the edges to make sure your window is sitting perfectly in the frame on your wall.

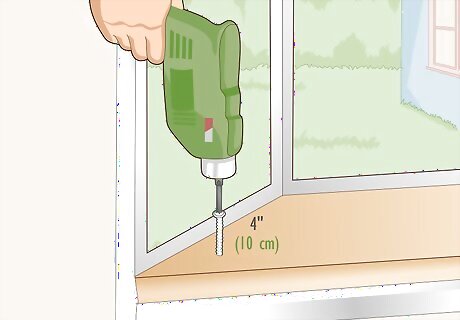

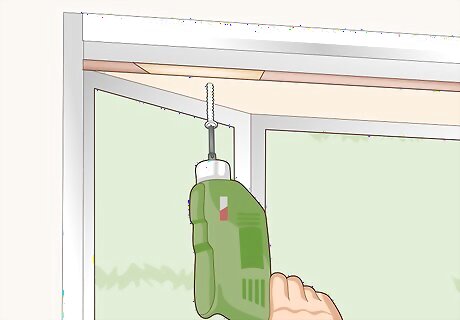

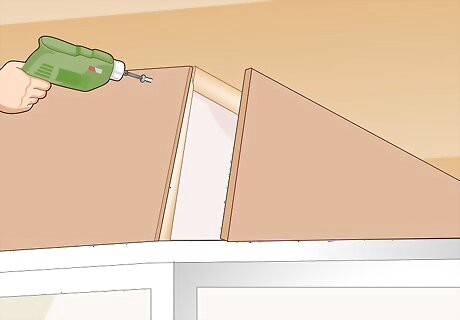

Drill 4 in (10 cm) wood screws into the interior frame to brace the window. Grab a handful of wood screws and a drill. Once the window is lined up, on the inside of the window, drill the top of the bay window into the joist above it. Place 1 screw every 4–5 inches (10–13 cm). Then, repeat this process on the bottom to hold the bay window temporarily in place while you work. If your window’s instruction manual tells you to use a different size screw or to temporarily hold it in the frame some other way, do that instead. You’re going to cover all of these screws anyway, so it doesn’t really matter if they aren’t beautiful. You can use a nail gun and framing nails instead if you prefer. Nails tend to be a little weaker than wood screws, but this is only a temporary measure so it may not matter if the window isn’t particularly big or heavy.

Drilling in the Support Cables for the Roof

Read the instructions to see how high the cables have to sit above the roof. The support cables are a system of industrial-strength cables that hold the bay window up. Read the bay window’s instruction manual to see how high your specific cables need to go. If your instruction manual doesn’t mention a height, install them at a 45-degree angle to the front of your roof. Typically, the cables go 16–24 inches (41–61 cm) above the bay window.

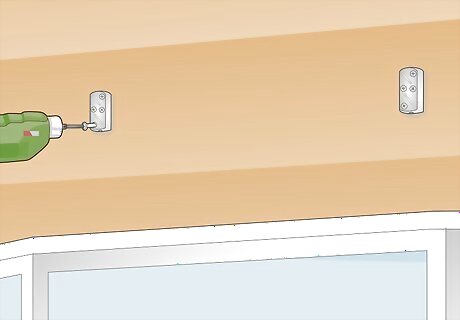

Drill your two cable clamps directly into the wood above the window. Each cable runs through a clamp that holds it in place. Get on a ladder and measure up from the base of your bay window’s roof to set your clamps at the recommended height or 45-degree angle. Place each clamp over the corner where the front of the bay window angles back to your home and drill each clamp into the exterior using the screws that came with your bay window.Tip: If you have any siding or shingles in the area where you’re installing the clamps, you must remove them. Cut a piece out with a utility knife and use a zip tool to remove the panel. You do not need to remove stucco or masonry. You can replace any missing siding later. Do not drill the screws in all the way. Leave a little bit of room behind each clamp for the cable. The clamp looks kind of like a small rectangle with an opening on the back for a cable to slide through. You always install the clamps vertically so the short side is facing down. The height of your clamps determines the angle of the support cables. The higher up the clamps are, the more support you have for the window. However, the size of the roof cab impacts how high you can set the clamps since the roof cab goes over them.

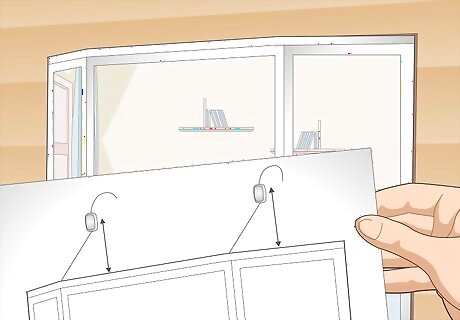

Slide the support cables through the bottom of the clamps. If you need to run your cables through a hook on your bay window’s roof, do so now. If the cables are already on your bay window, you don’t need to do anything. Run your first cable through the bottom of the cable clamp above it. Pull it through and let it hang. Repeat this process with your second cable on the other cable clamp. Sometimes, the cable comes preinstalled on the bay window. Other times, there’s a small hook for you to run the cable through on the window. Whether the cables are preassembled on the bay window or not depends on the manufacturer. There’s no structural difference between pre-installed cables and cables you run through a hook.

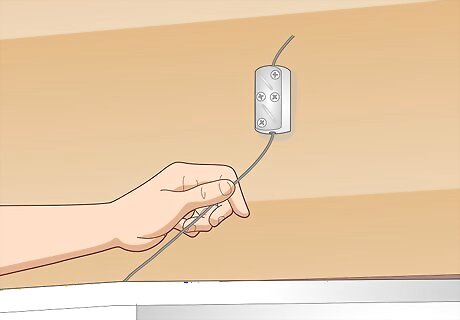

Tighten the cables by drilling the screws all the way through the clamps. Have someone stand on the inside of the window and rest a spirit level flat on the bottom. Continue pulling the cable through on the first side by hand until the bottom of the window is perfectly level. Then, tighten the screws on top of the clamp to pin the cable against the side of your house. Repeat this process on the other side. The cables are not holding your window up. They only keep the window level and counteract the gravity trying to pull it down.

Assembling the Roof and Adding Insulation

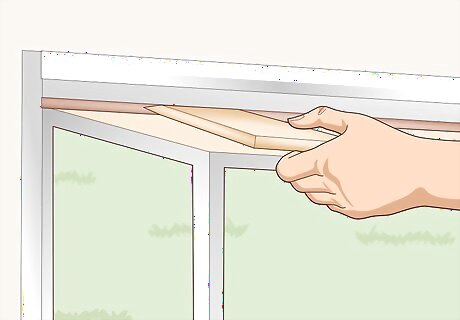

Slide shims into any openings around the window frame to keep it level. On the inside of your window, hold a spirit level against the sides and roof of the window. Inspect the opening between the wall and the window to ensure the space is even on each side. If any sides are not, slide wood shims between the window and the wall to artificially push on a side of the window and keep it even.

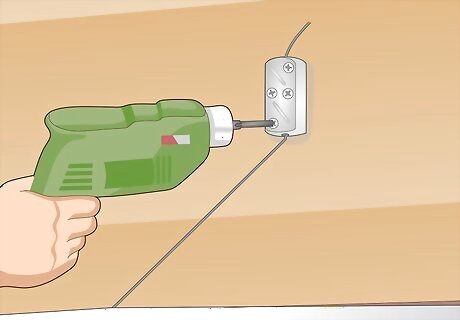

Drill the shims permanently into the surrounding wall. Grab a drill and some 3 in (7.6 cm) wood screws. Run a screw through each portion of the bay window where a shim rests underneath. Then, score each exposed portion of a shim with a utility knife and break it off with a mallet. This will keep the shims from sliding around in the wall after you finish installing the window.

Lay the roof cab down on top of the bay window. You can build your own roof cab, but it is exponentially easier to buy one from the manufacturer. Get on a ladder and set your cab down on top of the window. Line the front edges of the cab up with the front of your window and double-check the two angular corners to make sure they’re lined up.Variation: To build a roof cab, construct a wood frame out of 2 by 4 ft (0.61 by 1.22 m) boards that matches the base of your bay window’s roof and mirrors the shape at a 90-degree angle on your wall. Then, miter 4 joists at a 45-degree angle on both sides and install them around the exterior opening of the frame to reinforce it.

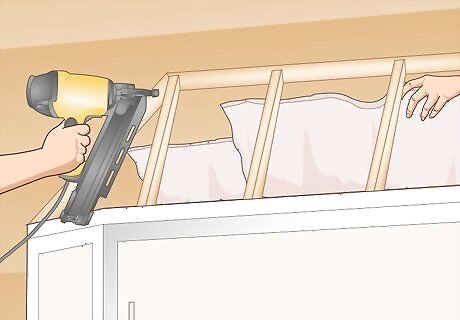

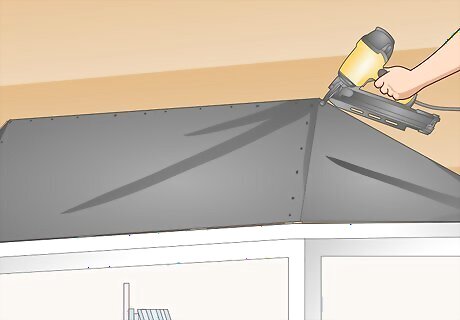

Nail the roof cab into place and fill it with insulation rolls. Grab a nail gun and load it with framing nails. Drive nails into the base of the frame where it attaches to the bay window. Repeat this process on the top to nail the roof cab into the wall it’s resting against. Space the nails out by placing one every 4–6 inches (10–15 cm). Then, lay down multiple sheets of blanket insulation inside of the cab to keep the window from getting too cold in the winter. Insulation sheets are typically filled with fiberglass. You must wear gloves when handling it to avoid cutting yourself. Blanket, or rolled insulation refers to the soft, pliable insulation sheets you find behind drywall. You can cut the insulation if you need to using a utility knife and a spare length of wood as a straight edge.

Cut and drill plywood decking into the roof cab if it isn’t prefabricated. Many bay windows come with the decking precut, but you must cut your own decking if it isn’t. Measure the dimension of each face on your roof cab and trace the shape on a sheet of plywood with a carpentry pencil and a straight edge. Cut the plywood with your circular saw to match the size of each face of the roof cab. Cut two triangles for the sides and one rectangle for the front. Nail the decking into the front of the roof cab to make your roof. Take your time when you’re lining up the plywood decking. It’s best if you have no exposed edges and you can’t see the cab underneath when you’re done.

Lay roofing paper over the cab and nail it into place. Roofing paper refers to paper sheeting that goes in between a roof and the shingles. Purchase a roll of roofing paper and cut it out into sheets using your utility knife and a wood board as a straight edge. Lay the roofing paper over the roof and nail it into the plywood underneath. There must be a 3–4 in (7.6–10.2 cm) lip at the top of the paper where it leads into the wall. If there isn’t, water may drip in between the window and the wall.

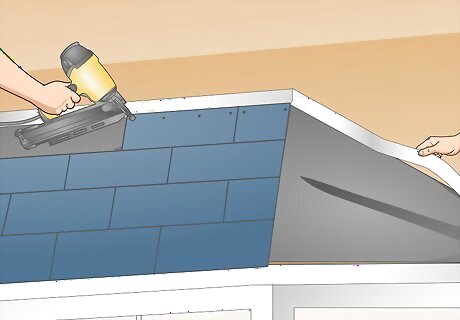

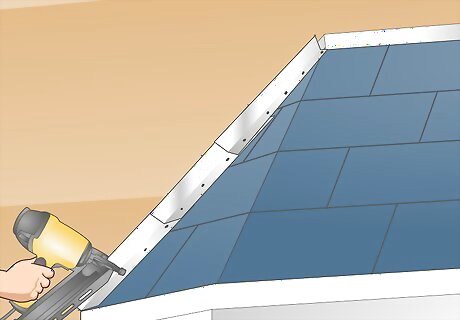

Cover the seams with flashing tape and install the shingles. Grab your roll of flashing tape and lay down strips around the edge of the roof where it meets the wall. Then, lay down your first row of shingles at the base of the roof. Nail your shingles into place and add additional rows above the first layer so that the shingles cover up the nails in the previous row. Use a hook blade to cut any shingles to size. You can install a metal roof made of prefabricated metal sheets instead, but you must order this roof in one piece from a company that makes roofing materials. You can’t cut one to size yourself. When you’re done with everything else, spread asphalt caulking in between the shingles to seal them and keep water from seeping through. Buy shingles that match the color and shape on your roof. If you don’t have shingles, you can use any style of shingle you’d like.

Install step flashing along the corners and top of the cab to keep water out. Step flashing refers to the metal strips that sit where a roof meets a wall. Purchase some step flashing and cut it to size with tin snips. Bend the flashing to match the shape of your roof where it meets the wall and nail it into place. You only need step flashing at the corners of the window and the top row, but you can install it along the entire rim if you’d like. Step flashing is really easy to bend by hand, but you must wear gloves to avoid cutting your hands.

Insulate the bottom of the window and cover it in plywood. Cut a sheet of insulation out to match the bottom of the bay window. Slide it into place underneath the bay window and put a sheet of plywood over it. Nail the plywood into the frame to hold the insulation in place. If you have a finishing sheet on the bottom of the bay window or any decorative brackets, you can screw these into the wall as well. For decorative brackets, you may need to cut out some siding if you have vinyl siding on your walls.

Sealing the Edges and Finishing Your Window

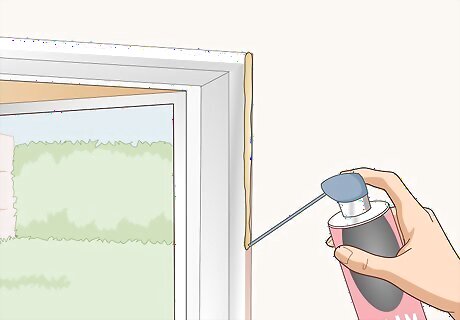

Seal gaps between the frame and the wall with spray foam sealant. Grab a can of spray foam sealant and stick the straw into the opening on the nozzle. Go inside and identify every gap between the window and the wall around it. Fill these gaps in with spray foam sealant and let the sealant puff up until it’s roughly flush with the wall. Wait 1 hour to give this spray foam time to dry. If you’ve ever done any demolition or repaired a window, you’ve seen spray foam sealant. This is that orange, puffy stuff behind chunks of drywall. It’s basically a type of insulation that keeps air and moisture from sneaking in through a gap in the wall.

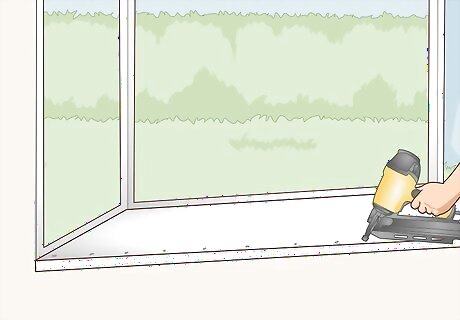

Nail your flat panels into place along the top and bottom of the window. There are two flat panels that match the shape of the window sill that came with your window. Take these flat panels inside. Hold one piece against the bottom of the window and nail it into the plywood or vinyl underneath using a nail gun. Repeat this process at the top with the second panel. These panels match the interior shape of the window at the top and bottom. Just slide them into place so all the edges line up with the glass and the edge of the window frame. Place your nails 1–2 inches (2.5–5.1 cm) from the edge of the frame so you can cover them with siding. Repeat this process for the interior strips that go on the side if you have any.

Attach your interior trim into place to finish installing your window. Cut each piece of decorative trim to match the seams around the side of the window, as well as the interior edges of the window. Use a nail gun and 2 in (5.1 cm) interior nails to attach the trim and cover up the seams where your wall or window panels are exposed. Cover the rectangular opening of the window and the base of the frame. Outside, cover any edges on the sides of the glass with vertical pieces of trim.

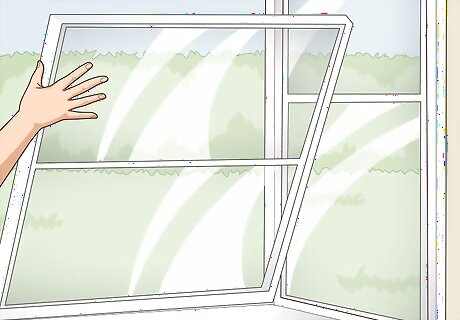

Slide the windows into the frame until they click in place. Lift your glass panels up and slide them horizontally into the opening they belong to. Slide each window up until it clicks into the frame. Repeat this process for each window to finish putting the glass in.Tip: Be careful when you’re installing the windows. If you end up dropping one it may cost you! Some bay windows come with the glass preinstalled. If this is the case, go ahead and skip this step.

Comments

0 comment