views

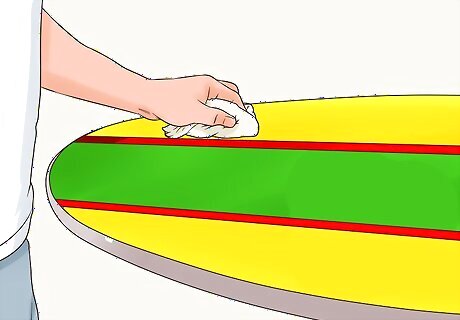

Cleaning the Cracked Area

Wipe the board down with a damp cloth to remove wax, salt, and sand. Before you can repair it, the board needs to be clean. Simply wipe it with a towel and freshwater to collect any sand or salt, and make sure all of the board wax is off of the surface, especially around the crack. Use a cotton swab to clean out the crack. Any particulate left inside or around the crack can get caught in the resin and cause the repair to be weaker.

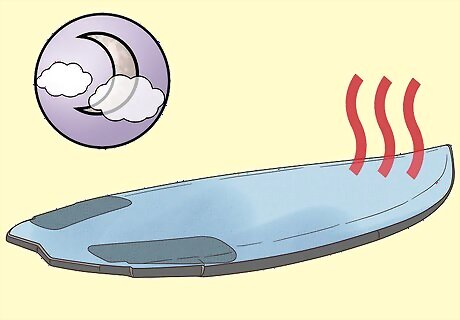

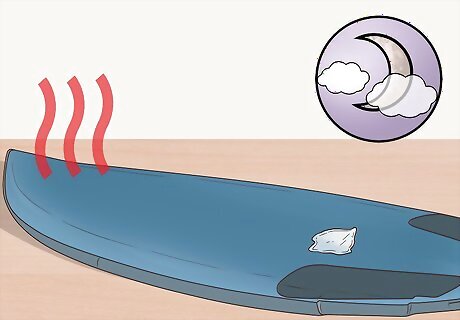

Let the board dry overnight. To prevent the repair resin from trapping water and causing mold to form, set the board out and let it dry completely. After at least 6 hours, check that the board is dry, and inspect the crack. Before you begin working, squeeze the crack to make sure no water leaks out. If the crack is still wet, or the board feels heavier in that area, allow it to dry for another 1-2 days before beginning your repairs.

Cut away any rotten foam from inside of the crack. If your board has been cracked for a while, or a lot of water got into the crack, you might have some rotten foam inside of your board. Look for brown or black foam that is soft to the touch. Use a sharp knife to slice through the foam in straight lines, and throw away any rotten foam that you remove. If you're having trouble seeing the foam, shine a light into the crack. Normally, you will be able to see the color of the foam inside the board.

Sand the crack with rough grit sandpaper down to the fiberglass cloth. Rub a rough sandpaper over the crack in the board, sanding an area slightly larger than the crack. Once the fiberglass cloth under the outer coating of the board becomes visible, stop sanding. Sanding a larger area is important because you want to blend the resin in with the surface of the board. If you don't do this, you run the risk of only repairing part of the crack.

Setting the Resin

Purchase UV resin online or in a surf shop. UV resin is great for small repairs or short-term fixes. It comes in liquid form and dries to a hard material after it's exposed to the sun. Search online or look in your local surf shop to buy the resin before starting your repairs. UV resin will hold up to most normal surfing dings and cracks for 2-3 months. After that, you will need to repair the board again or have it professionally repaired.

Make a mixture of resin and Q-Cell filler to replace rotten foam. Q-Cell filler acts as a replacement for the foam because it expands when it cures. Pour 1 fluid ounce (30 mL) of resin into a cup and slowly add the Q-Cell filler until the mixture is the consistency of toothpaste. You can find Q-Cell filler at most surf shops, or you can order it online through retailers like Amazon or eBay. If the crack is very large or you removed a lot of rotten foam, use 2–3 fluid ounces (59–89 mL) of resin to start out.

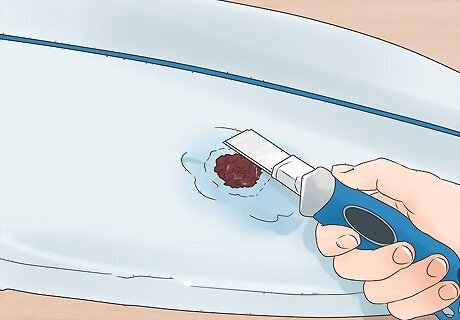

Use a wooden stick or spoon to apply resin liberally over the crack. In a covered area out of the sun, squeeze the resin into the crack first, and then smooth the resin over the crack. Make sure the resin is touching the outer shell of the board. As you're working, push any bubbles out of the resin as they form. Try to make the resin as smooth as possible on the outside, but don't worry if there are a few small bumps.

Cover the resin with plastic wrap to hold it in place. Once the resin is applied, wrap a piece of plastic wrap around the board and over the crack. This will hold the resin in place while it cures and mold it to match the general shape of the board. Try to avoid pressing on the plastic wrap after it's on the board, which can dent the resin before it cures. If you don't have plastic wrap, use a plain piece of clear plastic and tape it to the board.

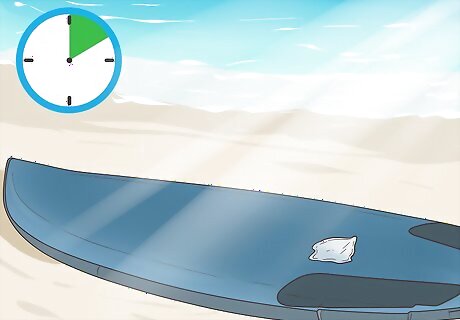

Expose the resin to sunlight for 5-10 minutes. Move the board into the sun to cure the resin. It will turn into a gel, and then harden after 5 minutes. Let it sit in the sun for an additional 5 minutes to harden completely. If the resin isn't hardened after 10 minutes, place it in the shade for 5 minutes, and move it back into the sun.

Finishing the Repair

Let the resin dry completely overnight. Although the resin is hard, it isn't completely dried yet. Don't touch the plastic covering or the cracked area while it cures. Let it sit undisturbed for at least 6-12 hours before removing the plastic wrap. Some resins require air to set. Check the directions on the packaging, and if necessary, remove the plastic wrap before letting it cure.

Sand off excess resin until it is flush with the board. Start sanding with a rough grit sandpaper to remove larger bumps and imperfections in the resin. Then, switch to a finer grit to smooth the resin to match the board. Once the resin is smooth, wipe away the debris and make sure the edges of the resin are flush with the rest of the board. You may need to sand the edges of the resin a bit more to ensure that it lays flat against the board and isn't wavy or bumpy. Be careful not to over-sand with the rough grit sandpaper. Once the major bumps are flattened, switch to a smooth grit to prevent divots from forming in the resin.

Add a layer of fiberglass and resin for added strength. If you're worried about your board cracking in the same place, cut a sheet of fiberglass in a circle slightly larger than the crack, and cover the crack with the sheet. Then, use a brush to apply a thin layer of resin over the fiberglass sheet. If you have a long crack in your board, cut a few smaller circles and line them up along the crack to cover the entire length.

Cure and sand the resin again if you added a fiberglass layer. Once the resin has cured overnight, use a fine grit sandpaper to smooth the resin overtop of the fiberglass. Continue sanding until the resin is smooth with the surface of the board. Only use fine grit sandpaper over the fiberglass. A rougher grit may remove too much resin and could expose part of the fiberglass.

Comments

0 comment