views

Reading the Pressure and Checking the Safety Valve

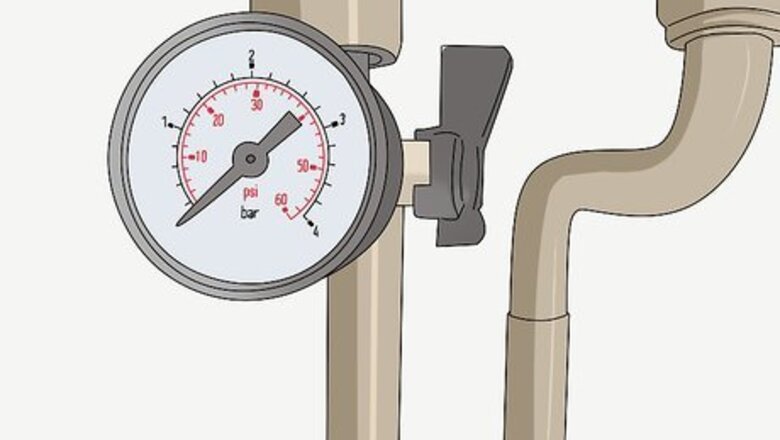

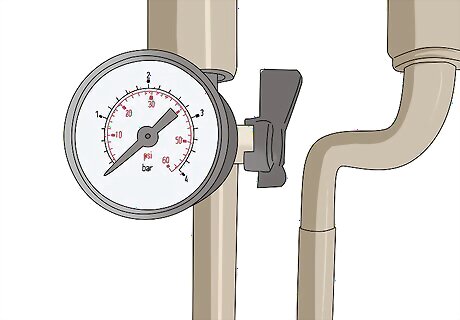

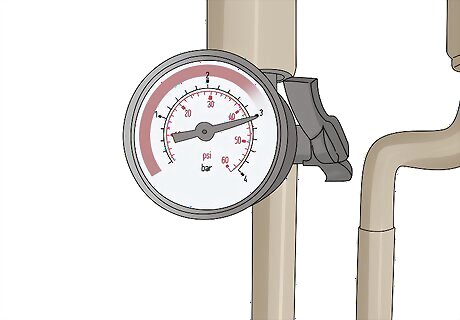

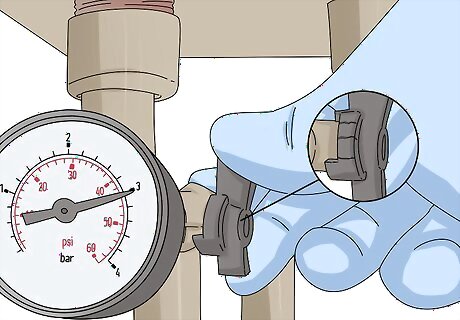

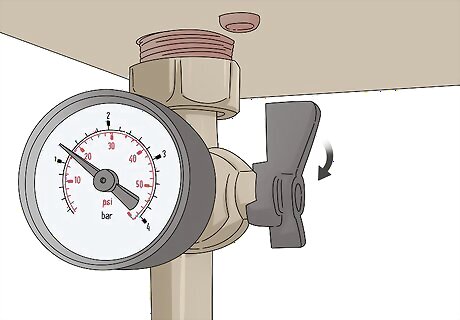

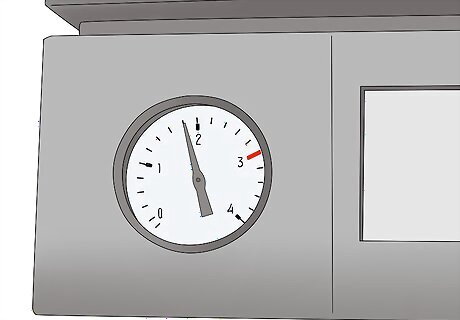

Find the pressure gauge on the front or side of your boiler. The pressure gauge is a circular object on the front or side of your boiler that tells you the boiler’s overall pressure level. It is usually in highly-visible area, but may be near the ground on the side of your boiler near the return line or release valve. Look for a gauge with a needle and numbers on it to find your pressure gauge.Tip: The pressure gauge is normally right next to a temperature gauge. If the pressure is high and your temperature gauge is in the red, call an emergency boiler repair company. High pressure and extreme temperatures can lead to explosions or damage to your property. Your gauge will read pressure in either bars or psi. Psi stands for pressure per square inch, while the bar is a metric unit of pressure (1 bar is roughly 15 psi).

Recognize that the pressure is high if the gauge reads higher than 3 bars or 45 psi. The pressure limits and ranges are different for each boiler depending on its size and type, but generally speaking, a pressure gauge should read between 1-2 bars or 15-30 psi. The pressure may be lower if it is warm out, or higher if it is cold out. If it nears 3 bar or 45 psi though, your pressure is too high. Pressure gauges are often color-coded. If the needle is in the green, your pressure is usually fine. Yellow typically means that the pressure is high, but acceptable. Red means that the pressure is too high or low.

Find the safety valve by looking on the top of the boiler. Look for a brass or metal valve with a cap on top attached to a pipe near the top of your boiler. The safety valve measures pressure in the boiler and releases air to relieve pressure when it gets too high. If your safety valve is broken or working improperly, it could be failing to release pressure. Don’t touch the safety valve without wearing thick gloves. It may be hot if it was recently releasing pressure. The safety valve will sometimes be attached to a pipe on the side of the boiler near the top.

Inspect the safety valve for cracks or steady streams of water. There is an open spout and closed cap on your valve. Take a careful look at the valve without sticking your eye near the open spout. It is normal for there to be a little bit of water on the open spout, but if you see any water coming out of the closed cap or pipe connection, your valve may need to be replaced. The valve should have no cracks in it. If you see a crack, it is time to replace the safety valve. Another possible sign that the valve is bad is if there is a constant flow of water coming out the open spout. Some drips or moisture is fine, but a steady, consistent flow is a problem. Contact a boiler repair specialist to replace the safety valve. This is not a repair that you can do without professional assistance, since an improperly-installed safety valve can cause an explosion.

Turn the heat on and check the heat on your radiators. If your pressure is high but there is nothing wrong with your safety valve, you may need to bleed your radiators. You can tell if a radiator needs to be bled if the upper portion of a radiator is cold or lukewarm when the bottom portion is running hot. If there is no heat at all when you turn the radiators on, you could have a larger issue with your pipes. Bleeding a radiator releases air pockets and bubbles from the radiator lines. Air can increase the pressure in your pipes while simultaneously lowering the amount of heat coming out.

Bleeding a Radiator

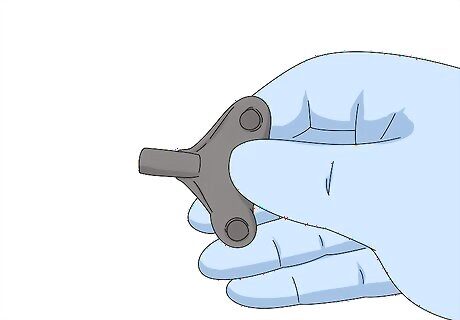

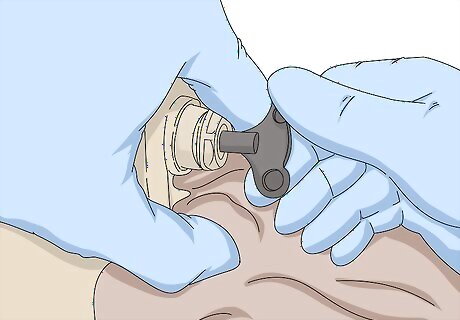

Get your radiator key or buy one from a hardware store. A radiator key is a small metal tool used specifically to open a bleed valve on a radiator. They are cheap, and usually come with a house or apartment when you move in. You can also use wrench or pliers to open a bleed valve, but a radiator key is specifically designed to open and close the valve without damaging it. Some valves have a slot on top so that you can use a flathead screwdriver. Some larger boilers are bled by turning the valve on the boiler itself. For these boilers, the overall process is similar except you’ll open a bleed spout on your boiler instead of the radiator. You’ll need to run a hose to a drainpipe to get rid of the excess water.

Turn off your heat by lowering the thermostat or cutting power to the boiler. Lower the thermostat so that the heat cuts off and won’t turn back on while you’re bleeding the radiator. If you can’t, flip the power switch on the side of your boiler to shut the power off. You may hear some crackling sounds from your radiators even after you’ve shut it off. Just to be on the safe side, turn your thermostat down at least 15-20 degrees F (or 2-3 degrees C) below the outdoor temperature.

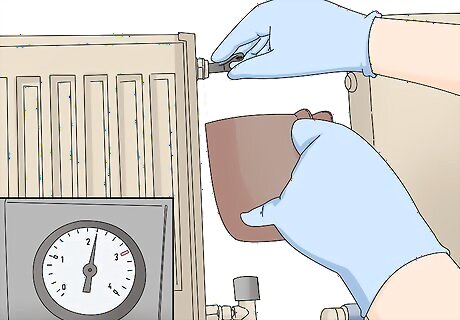

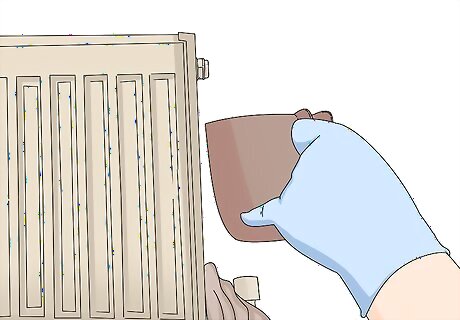

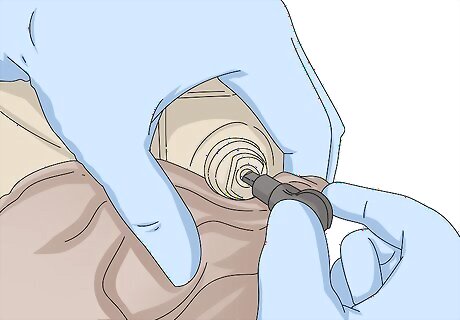

Put a bucket under the radiator bleed valve and get a cloth. The bleed valve is the small port on the side of a radiator near the top. Place a bowl or bucket under the valve and get a large, dry cloth. Put on thick gloves before touching your radiator.Warning: The radiator will be hot if it was running recently, so you have to wear thick gloves to protect yourself. Even if the radiator isn’t hot, bleeding it causes hot water to come out. It’s pretty easy to see a bleed valve. It will be the only object attached near the top of your radiator. If you’re bleeding the boiler itself, hook up a hose to the threading on the bleed sprout. This will look like a standard outdoor hose spout, and will be pointing downward near the bottom of your boiler. Some bleed sprouts point directly to a nearby drain.

Open a bleed valve near the top of your radiator with the key. Use the radiator key or tool to start loosening the bleed valve. Turn it counterclockwise once or twice until you start hearing hissing. This is the air leaving your pipes and a sign that your pipes are clearing! A little bit of water may come out while the air is emptying so keep the cloth nearby while it makes noise to catch or wipe up any water. It should only be a little bit of water, but that may change after a few seconds. Keep your key attached to the valve so that you can close it quickly. To open a boiler’s bleed sprout, simply turn the handle 2-3 times counterclockwise.

Close the valve when water starts flowing out. As soon as the hissing noise turns into the bubbling sound of water flowing, it is a sign that you are almost done. Once your radiator starts to release a steady stream of water, close your valve. Tighten it by turning it clockwise until you can’t turn it any further and the hissing noise has disappeared. On a boiler, run the water until it runs clear and doesn’t sputter.

Repeat this process on every single radiator in the building. Bleed your other radiators, even if they aren’t cold or lukewarm. Use your radiator key, bucket, and cloth to bleed every radiator in the building. Each time you bleed a radiator, you’re removing the air pockets in the pipes leading up to that unit. By bleeding every single radiator, you ensure that all air is removed from the boiler system.

Solving Uncommon Problems

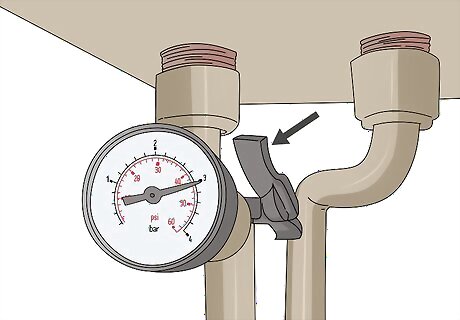

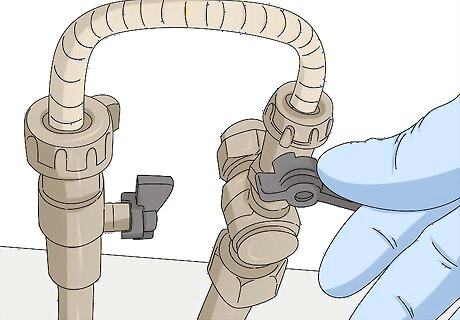

Close the valves on the filling loop if they're open. The filling loop is a thin, U-shaped pipe that connects 2 pipes under or next to your pressure gauge. The filling loop is used to refill your boiler from the water main. If it is left open, it may be feeding a constant supply of water to your boiler, causing the pressure to increase. Make sure that the filling loop’s valves are closed by rotating the tab on top of each connection so that it runs perpendicular to the pipe and stays closed. If you ever bleed all of the water out of a boiler, you use the filling loop to refill it. Put your ear next to the filling loop. If you hear water coming through it, it is a sign that it is open. The filling loops may be soft and pliable like the supply lines under a sink.

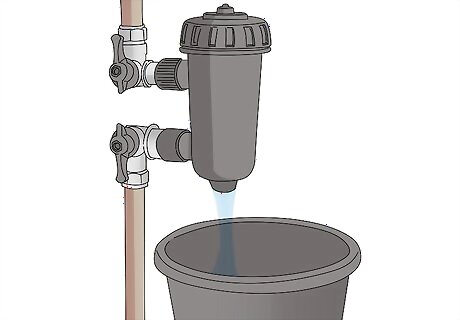

Remove debris by draining a little bit of water out of the filter. Newer boilers come with filters that prevent debris in the pipes from returning to the boiler. Your filter may be filled with bigger pieces of debris that are blocking the flow of water and increasing pressure. Get a large bucket and set it out underneath the spout. Turn the spout to release water and wait for the pressure on your gauge to drop. Once it does, retighten the spout until it is closed.Warning: This can be dangerous if you’ve never done it before. The water may be quite hot and it come out very quickly. Consult a professional if you’re not familiar with your boiler’s filtration system. If the pressure doesn’t drop as you’re emptying the filter, you could have a faulty pressure gauge. The filter is a larger container attached to a pipe next to the boiler. It is usually plastic and built into a pipe near the pressure filler loop. Older furnaces don’t tend to have filters.

Monitor the pressure control boxes to see if they’re operating normally. The pressure control boxes are self-contained mechanisms that regulate the pressure on larger boilers automatically. They are usually on the side of a furnace or on a nearby wall and they look like clear thermostats. While your boiler is running, watch your pressure control boxes to make sure that they click on and off as your boiler turns on and off. If more than 1 of them is clicking at a time, contact a boiler repair specialist to diagnose problems with them. Each box performs a different function. The first 2 boxes control when the boiler automatically cuts on and off. The other 2 automatically regulate pressure increases and decreases. If all 4 of them are clicking at the same time, something is wrong with your system. Many pressure control boxes have small vials of mercury in them. If you see 2-4 boxes with little tubes filled with a silver liquid, these are your pressure control boxes. You can’t really do anything about your pressure control boxes without the help of a professional. Some of them are filled with mercury, but even if they aren’t, they’re incredibly complicated parts and require an experienced hand to adjust them. Look at the top and sides of each box. If there is a small button labeled “reset” you can press it to automatically reset the boxes.

Comments

0 comment