views

Bending Plywood with a Form

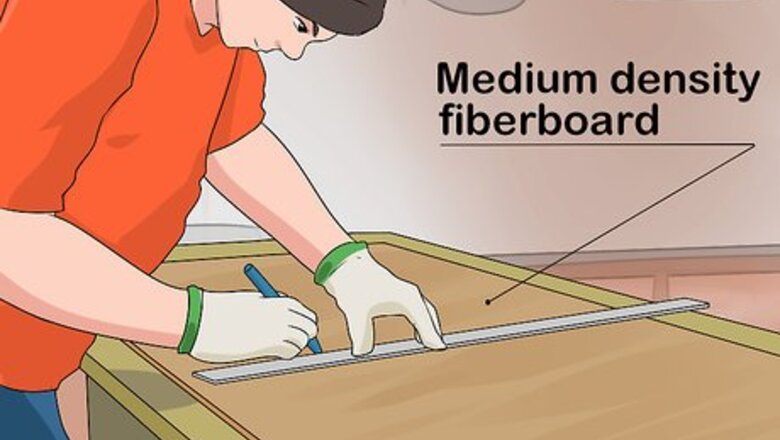

Create a form out of MDF (medium density fiberboard). Use a pencil to draw the shape of the curve you want to bend the plywood to on a piece of MDF. Cut out the shape using a bandsaw. Trace the shape onto more MDF and cut out more layers for the form. You want enough layers that the height of the form is about the same as the width of the plywood you’re trying to bend. Glue the layers of MDF together to complete the form. You can find medium density fiberboard at your local hardware store. Always wear protective eyewear when using a bandsaw. You can even use a jigsaw to cut it.

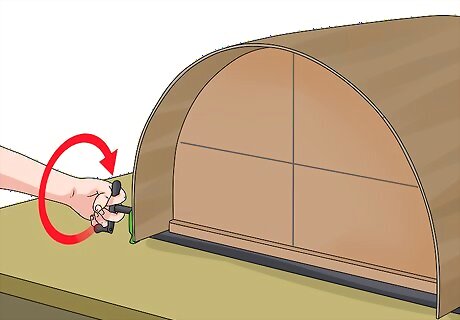

Clamp the plywood to the form using bar clamps. Place the piece of plywood next to the curved side of the form. Place one end of a bar clamp on the far side of the form, and the other end of the clamp on the outside-facing part of the plywood directly across from it. Spin the handle on the clamp clockwise to tighten the plywood into place against the form. Continue adding clamps to the plywood until it’s completely clamped along the curved side of the form. Make sure you clamp the ends and middle of the plywood you’re bending. If you see gaps between the plywood and the curved side of the form, tighten a clamp over them.

Leave the plywood clamped to the form overnight. This will give the plywood enough time to bend under the pressure of the clamps. Don't rush this step; if you take the clamps off early the plywood may not hold its curve.

Unclamp the plywood from the form. Twist the handles on the bar clamps counterclockwise to loosen and remove them. Once all the clamps are off, remove the plywood from the side of the form.

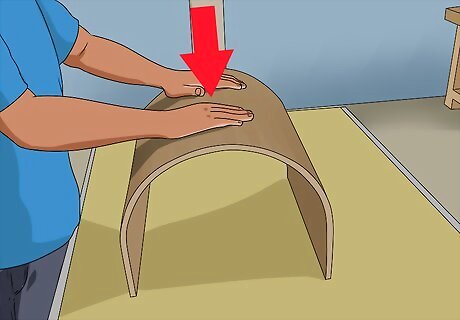

Use your hands to test the bent plywood. Try gently bending the ends of the plywood to see if it straightens out or holds its curve. Turn the plywood upside down so it’s resting on the ends and push down on the center of the curve with your hand. If the curve doesn’t hold, re-clamp the plywood to the MDF form. If you still can’t get the bend to hold, try gluing additional layers of plywood over your original piece and re-clamping it to the form. Making the plywood thicker will help it bend more easily.

Using a Ratchet Strap

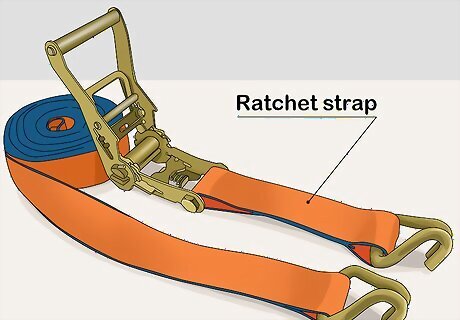

Get a ratchet strap with S-hooks. A ratchet strap, also known as a tie-down strap, is a nylon strap with a hook on each end. There’s a ratchet in the middle of the strap you can use to tighten the strap. Make sure the strap you get has S-hooks so it’s able to hook onto the plywood. You can find a ratchet strap online or at your local hardware store. Read the label to see if the ratchet strap has S-hooks.

Hook the S-hooks to opposite ends of the plywood. Center the hooks on the end they’re hooked onto. Do this with the piece of plywood lying flat so the S-hooks don’t slide off. Once the hooks are on, the ratchet strap should run down the center of the plywood, with the ratchet somewhere between the 2 hooks. You may need to thread the strap attached to one of the hooks through the ratchet so both sides of the strap are connected.

Use the ratchet to tighten the strap until the plywood is bent how you want it. To tighten the strap with the ratchet, bring the handle of the ratchet up and down repeatedly. Each time you lift up the ratchet, it will pull in some of the slack. Continue lifting and lowering the handle on the ratchet until the plywood is bent to your desired curve.

Leave the ratchet strap on the plywood overnight. After you’ve let the plywood sit overnight, remove the ratchet strap. To remove the strap, lift the handle on the ratchet and pull it all the way back so it’s flat on the strap. You should hear a clicking noise and the ratchet should stay open. Remove the S-hooks from the ends of the plywood.

Test the bent plywood. Place the bent plywood on a flat surface so it’s resting on the ends. Apply pressure to the center of the curve with your hands to see if the plywood straightens out. If the curve doesn’t hold, re-attach the ratchet strap and let the plywood sit for longer. You can also glue additional layers of plywood to the curved plywood, using clamps to hold them in place. The more layers there are, the stronger the plywood curve will be.

Comments

0 comment