views

- FEMA has a guide to building your own biomass gasifier, which converts wood chips into synthetic gasoline.

- There's also the Fischer-Tropsch process, which converts biomass into liquid fuel.

- Ethanol works as synthetic gasoline. You can make your own ethanol through DIY distillation or using a commercial ethanol maker.

Utilizing Biomass Gasifier Plans

Search online for “fema gasifier” to find an essential guide. In 1989, the U.S. Federal Emergency Management Agency (FEMA) published a guide called “Construction of a Simplified Gas Generator for Fueling Internal Combustion Engines in an Emergency.” This document has become the go-to guide for skilled DIYers who want to try their hand at creating synthetic gasoline out of wood pellets or chips. Find a good pdf or similar electronic copy at sites like: https://www.driveonwood.com/static/media/uploads/pdf/fema_plans.pdf Also download the “Handbook of Biomass Downdraft Gasifier Engine Systems” at https://www.nrel.gov/docs/legosti/old/3022.pdf

Get a handle on how gasification works. Section I of the FEMA guide provides a wealth of background information on the history and science behind the process known as gasification. It points out, for example, that all combustion (including in internal combustion engines) involves vapor, and that it is therefore possible to filter and isolate combustible vapor from burning biomass such as wood pellets. Biomass gasifiers don’t create liquid fuel, only combustible vapors. However, it’s important to remember that internal combustion engines vaporize liquid fuel anyway. Section I also presents an interesting historical account of the process, including how widespread the use of biomass gasification was in Europe during World War II.

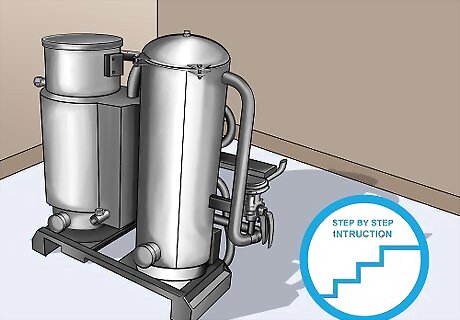

Follow the step-by-step instructions if you want to try building a system. FEMA created this guide for use by Americans during crises in which gasoline supplies might be cut off. So, the biomass gasifier it describes uses widely available parts such as a metal trash can and sections of piping. However, that doesn’t mean building the gasifier is an easy job that everyone can handle. In basic terms, the wood pellets or shavings are burned in one chamber of the gasifier, the smoke is filtered through more wood pellets/shavings in a second chamber, and the filtered vapor is mixed with air as it enters the intake valve of the internal combustion engine. You’re using fire to create combustible vapors, so it’s essential that you follow the directions very closely and take every recommended safety precaution. You may also benefit by watching online videos that show DIYers building gasifiers based on the FEMA plan, such as https://youtu.be/a6e3CprVTi8?t=220.

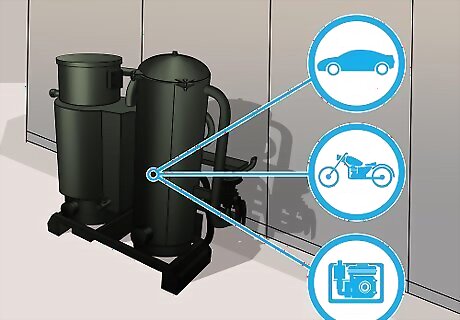

Power motor vehicles or a generator with a completed gasifier system. The FEMA guide shows you how to attach the gasifier to a standard farm tractor and use it to power its engine with wood shavings. In theory, you could use the same principles to power a typical automobile in an emergency situation—this wouldn’t be “street legal” under normal circumstances, though! In reality, this type of gasifier is probably more useful as a way to power a gas-fueled generator, which in turn can generate electricity for your home. This way, you can keep the lights on in your home with little more than some scrap wood.

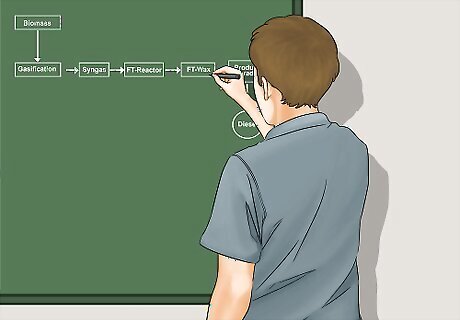

Researching the Fischer-Tropsch Process

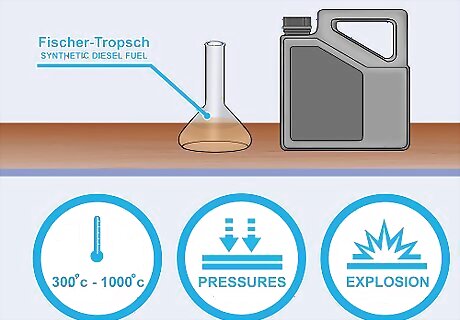

Learn how Fischer-Tropsch creates liquid fuel out of biomass. In very basic terms, the Fischer-Tropsch process adds high temperature, high pressure, and a heavy metal catalyst (like iron or cobalt) to the typical biomass gasification process. As a result, it can be used to create liquid synthetic gasoline out of biomass like wood pellets or organic trash. The high heat and pressure convert the biomass into a mix of carbon dioxide and hydrogen, at which point impurities can be filtered out. Then, the introduction of a heavy metal catalyst turns the carbon dioxide and hydrogen into long-chain hydrocarbons that are cooled and condensed into a liquid.

Accept Fischer-Tropsch’s limitations as a DIY project. Fischer-Tropsch has great DIY appeal because, unlike biomass gasification that produces a combustible vapor for immediate use, it produces liquid fuel that can be stored and used as needed. However, while it’s theoretically possible to replicate using widely-available materials, creating a Fischer-Tropsch converter is likely beyond the capabilities of most people. It relies on temperatures of at least 300 °C (572 °F) and preferably 1,000 °C (1,830 °F), and pressures of up to tens of atmospheres. This makes it extremely challenging--and dangerous, due to the risk of an explosion--if you don’t have advanced mechanical and scientific knowledge.

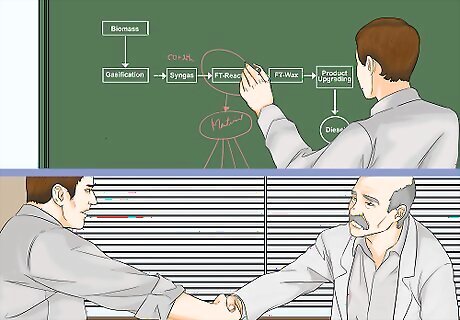

Get detailed plans and expert assistance if you wish to proceed. If you’re eager to try building a Fischer-Tropsch converter, research it thoroughly and study several conceptual designs. If you’re not a mechanical engineer, you’ll almost certainly need to find one to help you construct the converter. You may also need to check with local authorities to see if this is legal to build where you live. While the basic building materials are widely accessible—things like steel piping, pressure gauges, etc.—you need expert precision and knowledge to build a Fischer-Tropsch converter effectively and safely. Putting combustible materials under high pressure creates a major risk for explosions if the converter isn't built and maintained properly.

Don’t expect to save money on fuel this way. A Fischer-Tropsch converter lets you create liquid synthetic gasoline out of widely available materials like wood chips, so it is potentially valuable in an emergency situation. However, for general use, it is far more expensive to create fuel this way than to purchase typical gasoline. So, unfortunately, this isn’t a “magic bullet” replacement for gasoline derived from crude oil. Fischer-Tropsch fuels, however, do burn cleaner and create less environmental pollution than standard gasoline.

Looking into Ethanol Production

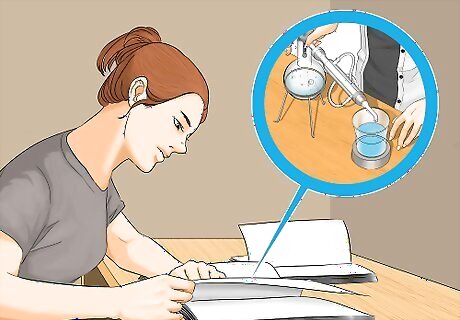

Research the process of distilling ethanol at home. Ethanol fuel is nothing more than distilled alcohol. So, essentially, if you can learn to make moonshine, you can learn to make a gasoline alternative. With some good plans and a bit of DIY know-how, you can build a simple still out of items like an old hot water tank and some conduit piping and produce ethanol yourself. Home production of ethanol on a small scale (under roughly 5,000 US gal (19,000 L)) is legal in the U.S., but check with your local authorities for any restrictions where you live. Take the time to find good plans for building a still, and consider working with someone experienced with the process. Heat and pressure are utilized to create ethanol, and these can be dangerous with improperly-constructed equipment.

Look into buying an all-in-one home ethanol maker. If building a still and making your own ethanol “moonshine style” isn’t your thing, you may have other options. Search online for companies that produce and sell ethanol fuel makers. With one of these machines, all you really need to do is add sugar, yeast, and water, push a button, and wait for it to produce ethanol for you. These machines can be the size of a stacked washer and dryer and may include a pump for direct fueling into cars, etc. However, expect to pay around $10,000 USD for one of these machines. Also, depending on the cost of the raw materials (namely sugar), producing ethanol this way may cost more than filling up your car with traditional gasoline.

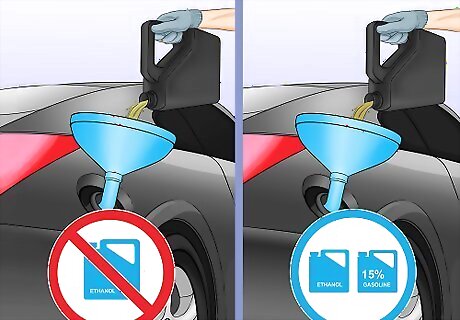

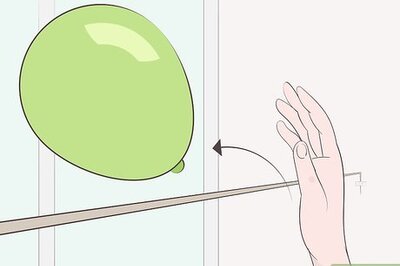

Don’t add straight ethanol to a standard internal combustion engine. If you want to power your car, lawnmower, etc. on ethanol, you need to blend it with at least 15% gasoline first. Otherwise, you risk damaging your engine. However, if you have a modern flex-fuel vehicle, you can fill it up with straight ethanol. It’s also possible to convert a standard engine so it can run on straight ethanol. For a car engine, this involves things like resetting the ignition timing and rejetting the carburetor. Unless you're knowledgeable in auto repair, you'll need a mechanic to make these changes.

Comments

0 comment