views

Threading a Serger

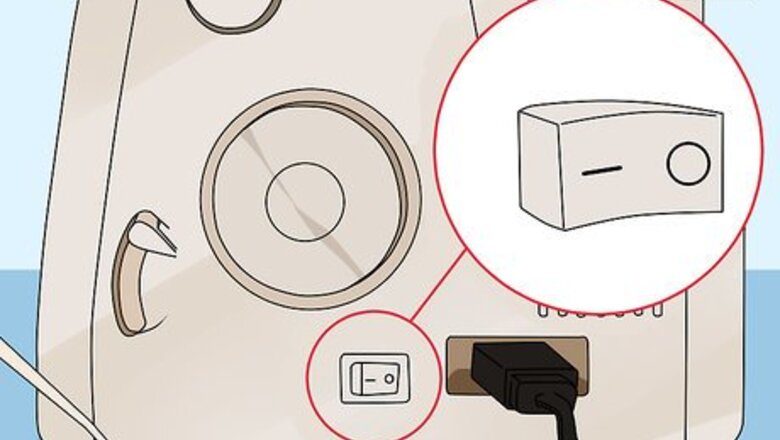

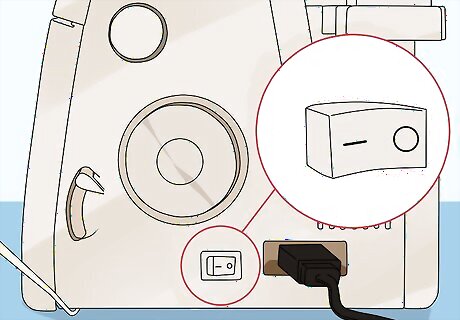

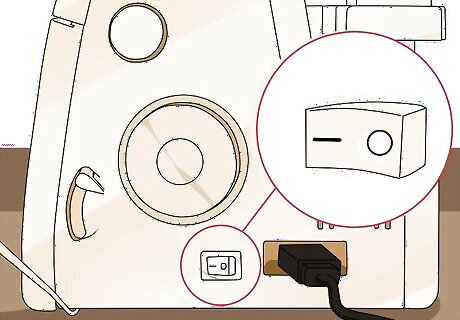

Turn the machine off. A serger should be off when you thread it. Locate your sergers power button and switch it off.

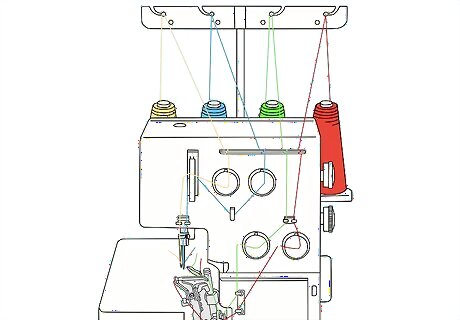

Determine the correct threading order. Most sergers use four spools of thread: two for looping underneath the needles and two to use in the needles. The model you have will tell you the order in which you thread them. Look at the threading diagram on your machine. A 3-thread machine has an upper looper, lower looper and a single needle thread.

Place a spool of thread on the upper looper. More than likely the upper looper will be on the right side of the machine. Set a spool of thread on the correct spindle for this.

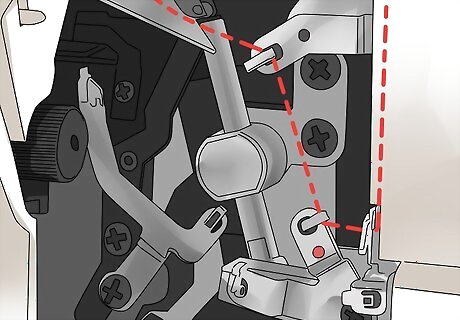

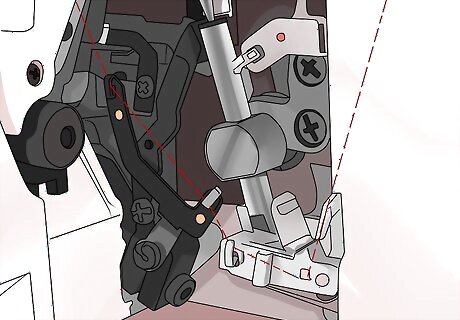

Thread the upper looper. Pull the upper looper thread up so that it is just below the needles. Remove the faceplate on the machine's front and pull the thread through the metal loops underneath the plate. Your serger will most likely have a color-coded guide to help you thread the upper looper.

Thread the lower looper. Set the spool on the second spindle and bring the thread over the front of the machine. Use tweezers to help you get the thread through the tight spots on the machine.

Thread the needles. Set the threads on the spindles and bring them over the front of the machine. Put the thread through the needle or needles on the overlock sewing machine.

Adjusting the Tension

Turn on the serger. You will need to use your serger to adjust the tension, so switch the power button on.

Determine what stitch you want to use. A serger can do many things like create a rolled hem, finish raw knit edges and gather fabric. Look at your user manual to determine what stitch you need to use for your desired result.

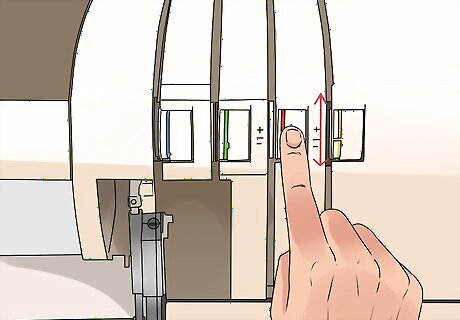

Adjust each spool’s tension dial. After you decide on what effect you want, your manual should tell you the required tension for each spool. Adjust each tension dial accordingly.

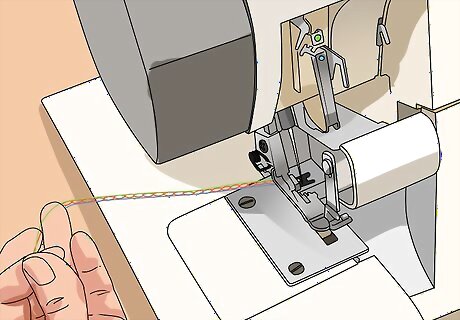

Run a practice stitch. You do not need fabric under the needles to test a serger stitch. Place your foot on the machine pedal and let the machine create looped thread.

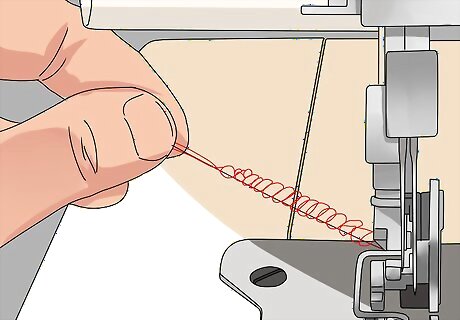

Inspect the looped thread. You should have an idea of how your stitch should look by looking in your serger’s user manual. The loops and interlocking stitches should be even, without areas that are too even or too loose. If the stitches are loose, adjust the tension dials next to each spool of thread on the overlock sewing machine to make the thread tighter. If the fabric is puckered or bunched up, loosen the tension on the serger.

Practice on a scrap of fabric. Find a piece of scrap fabric to test your stitch. Continue to sew practice stitches until the stitches are even. Always do a practice stitch whenever you change your needle, thread, or any other part of the machine. That way, you can make sure that everything is in place and working properly.

Finishing Seams

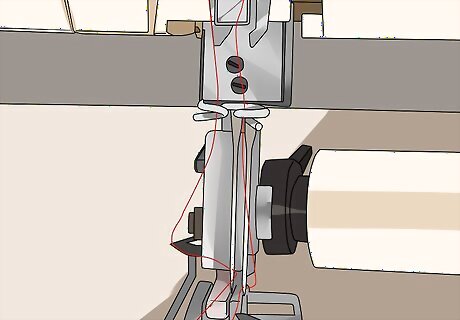

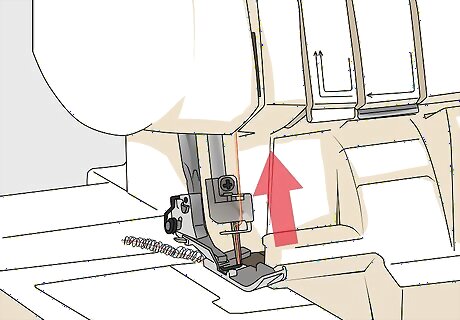

Lift the presser foot and needles. Lift the presser foot lever up to lift the metal presser foot and turn the needle dial towards you to lift the needles.

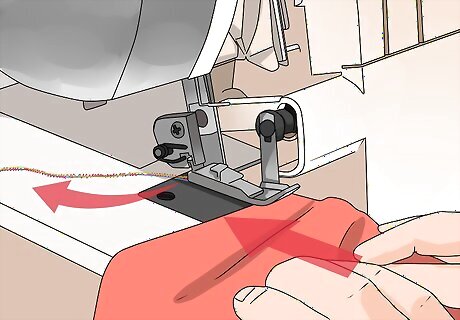

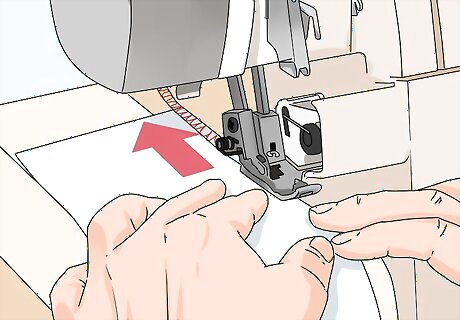

Push your fabric under the needles and foot. Lift your practice string up and back while you slide your fabric under the presser foot and needles.

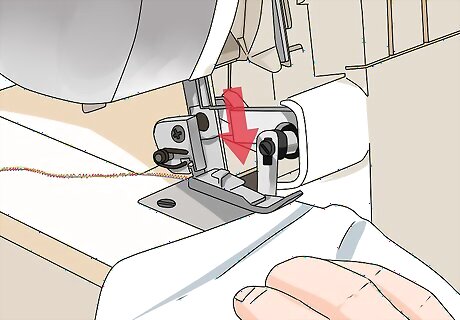

Lower the presser foot and needles. Lower the presser lever to lower the foot and turn the needle dial towards you to lower the needles.

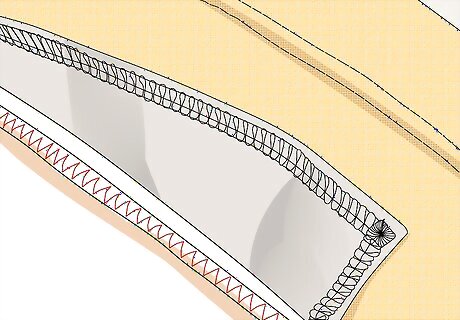

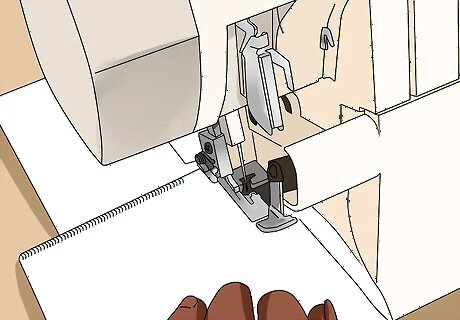

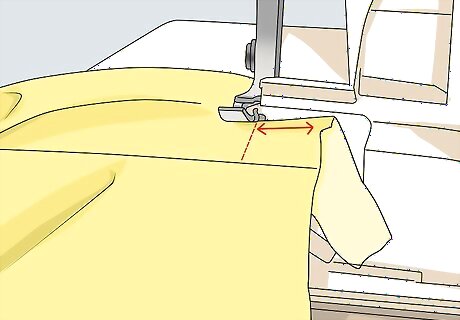

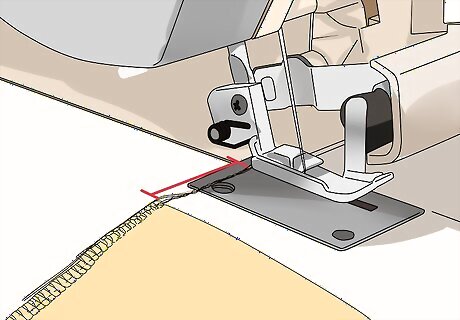

Cut the fabric edge. A serger will finish seams and cut your fabric at the same time. Look at the seam allowance numbers to the right of the needle and push the fabric past the blade accordingly. This can be 1.5 to 2.5 cm depending on what seam allowance you used when measuring your fabric.

Sew and guide fabric under the needles. Use the foot pedal to control the speed when sewing. Don't push on the fabric too hard and remember to keep the fabric straight. The feet on the overlock sewing machine should help push the fabric through.

Create a tail of stitches. Continue sewing for a few stitches at the end of your seam to create a tail of stitches that you can tuck under and hand sew in place.

Comments

0 comment