views

Taking off a Common Toilet Seat

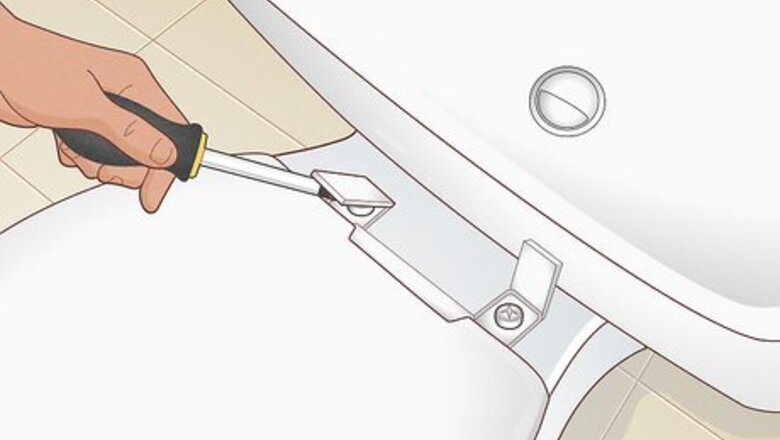

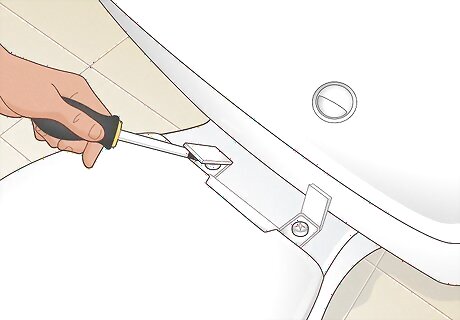

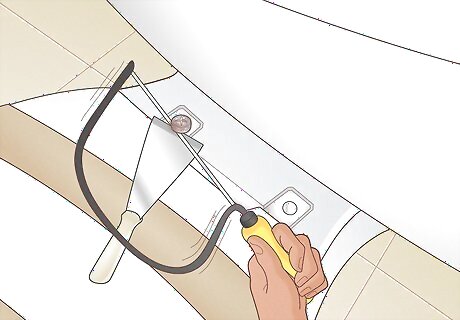

Open the bolt caps to gain access to the seat fasteners, if necessary. These are located at the back of the seat, where the seat hinges. Some toilets may not have plastic covers for the bolts. If yours does, open these covers by prying upwards on them with your finger or a screwdriver. Use light pressure when opening the bolt covers. Generally, it takes little pressure to open these, and using too much force may cause damage to them.

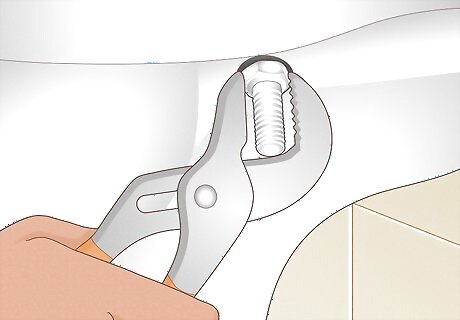

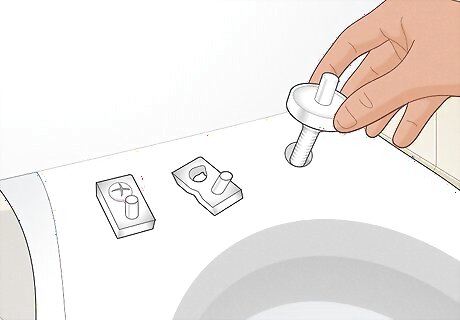

Grip the nut fastening the bolt firmly. You should find a nut screwed onto the threaded end of each bolt. Some nuts may have a shape similar to a wingnut, allowing you to hold it in place by hand. If you have a weak grip, the nut is not wingnut-shaped, or the nut is stuck, try gripping it with a pair of pliers or vice grips. The fasteners of your toilet seat may be plastic. Use light to moderate pressure when removing plastic hardware to keep it from breaking or deforming.

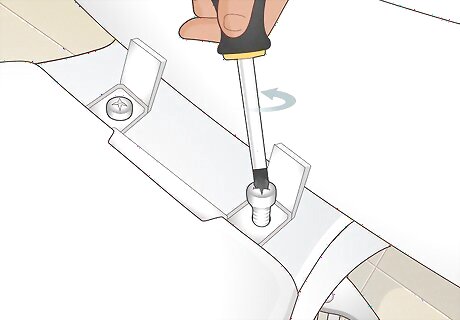

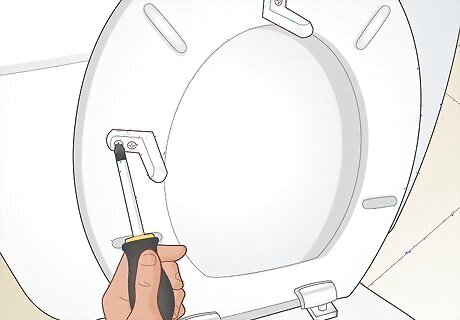

Unfasten the bolts with the appropriate tool. In most cases, you’ll need to unscrew bolts with a standard screwdriver. While holding the nut on the threaded end of the bolt, insert your screwdriver into the bolt head and turn it counterclockwise to unscrew the bolt. Screwdrivers that are too small can cause the bolt head to deform, especially if the bolt is plastic. Use the largest size screwdriver that will fit your bolt head for best results.

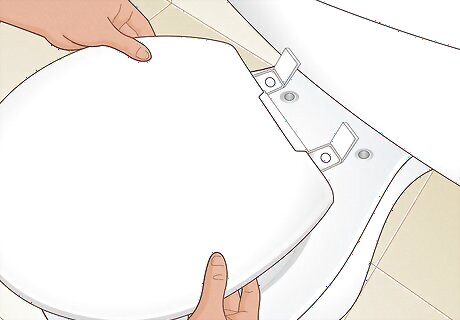

Remove the seat from the toilet. Collect the nuts, bolts, and any loose plastic or metal hardware (like the bolt covers) that also go with the seat. Put these small pieces into a sealable plastic bag and tape them to the seat so they don’t become lost. Your toilet seat is removed, now you can install a new one.

Detaching Stubborn Seats

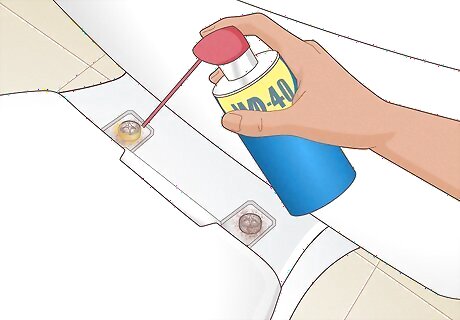

Lubricate corroded metal hardware with a penetrating oil. Penetrating oil, like WD40, is intended to revitalize metal parts that have rusted. Spray metal hardware, like nuts and bolts, thoroughly with this oil to lubricate them so you can remove them more easily. Wait about 5 to 10 minutes for the penetrating oil to seep into the narrow spaces of the hardware and break up corrosion. If you don’t have penetrating oil on hand, you can mix together a solution that is 90% vegetable oil and 10% acetone to make your own.

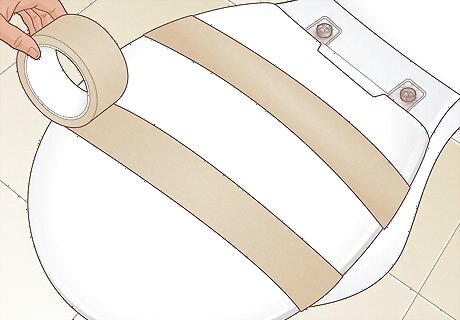

Secure the seat with tape. While applying various stubborn seat removal techniques, it’s likely you’ll jostle the seat or push against it. Depending on your situation and the kind of fasteners used to attach the seat, you may want to tape the lid and seat together in a closed or open position. If your situation requires you to cut or drill off bolts to remove the seat, you may want to tape a cover material, like cardboard, in place to protect the porcelain of the toilet and the plastic of the seat as well.

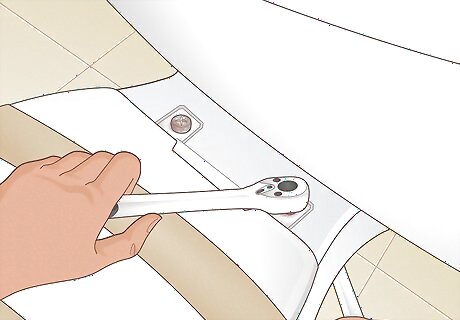

Remove the bolts with a socket set. In some cases, you may be able to directly fit your socket wrench onto the nuts holding bolts in place. Some toilet designs may require a deep socket or socket extension for you to reach the nut. Turn the socket counterclockwise firmly to break the nut loose. Apply steady moderate force with your socket wrench. If the nut doesn’t loosen, intensify the force on your wrench to high for a very short interval. Do this several times until the nut loosens. If the nut and bolt are already loose, the bolt may turn with the nut when you attempt to loosen it. Insert a screwdriver into the head of the bolt to hold it in place, then loosen the nut with your socket wrench.

Cut through unmoving hardware with a hacksaw. Take a broad knife, like a putty knife, and position it so it covers the porcelain of the toilet around the head of a bolt. This will protect against accidental scratches when you saw. Cut away at the hardware fastening the seat to your toilet a little bit at a time with the hacksaw. This process may take a while. A regular hacksaw will be able to cut through unmoving toilet seat hardware, but a mini one will be easier to use in the narrow space. Depending on the hinge of your toilet seat and the hardware connecting the seat to the toilet, you may have to cut through the hinge mounts and remove the seat with the bolts attached. Then, you can cut through the bolts.

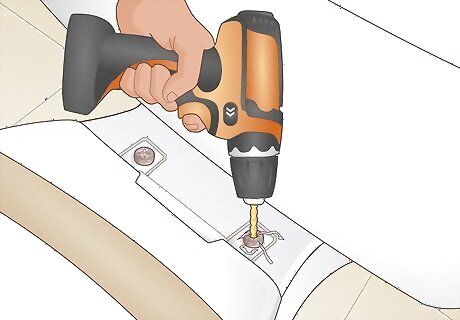

Drill through resistant bolts as a last resort. Put on safety glasses. Insert a thin drill bit, like on that is 1/16 in (1.59 mm) thick, into your drill. Drill into the bolt with firm, steady pressure where the nut and bolt meet. Drill through the nut completely, then use increasingly larger drill bits to widen the hole. Remove the nut when it comes loose. Save this technique as a last resort because there is a possibility that the drill bit might slip, causing damage to the porcelain or the seat. When you’ve almost drilled through the entire nut, be very careful. Drilling into the porcelain or the seat may cause unsightly damage. Drilled metal may have burrs or jagged edges that can cut you. Handle drilled metal with gloves. Use pliers to try to pull the bolt off. Continue enlarging the hole as necessary and pulling at the nut with pliers until it comes free.

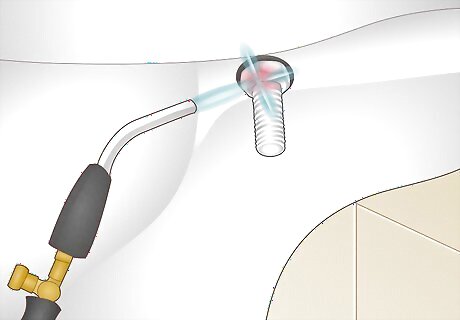

Use caution when loosening the nuts with a propane torch. If none of the other strategies are effective or you don’t have enough room to drill through the bolts, you can loosen them with a propane torch. Use a low flame setting and put a piece of metal between the torch and the porcelain so as not to damage it. Heat the stubborn bolts for a few seconds, then try loosening them with vice grips. Take care not to burn yourself and keep a fire extinguisher nearby when working with a propane torch.

Maintaining Your Toilet Seat

Clean the seat and its hardware regularly. Dirtiness and buildup can contribute to the corrosion and degradation of your toilet seat and its hardware. For this reason, you should clean it regularly with a suitable general purpose bathroom cleaner. Check cleaners before using them on toilet porcelain or the seat itself. In many cases, abrasive cleaners should not be used on toilet seats. Check the labels of cleaners to verify their suitability.

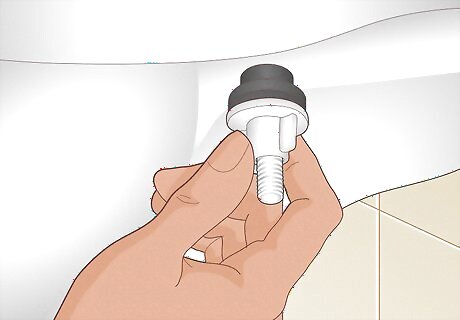

Tighten nuts with rubber bushings. Rubber bushings can be bought at your local hardware store or home center. Slide the circular, rubber bushings up the threading side of the bolt with the tapered side of the bushing facing up at the toilet. Then tighten the nut with the tightening tool that came with the bushings. Many hardware stores will sell this product under a name like "Toilet Seat Tightening/Fastening Kit." Alternatively, you can apply clear silicone to the areas where the seat attaches to the bowl. This will prevent the seat from sliding around.

Add seat stabilizers to loose seats. Seat stabilizers can also be purchased at your local hardware store. Fasten these to seats that wiggle back and forth. The stabilizers should touch the inner rim of the toilet bowl. When the stabilizers are in position, fasten them permanently in place with the screws that came with the stabilizers.

Replace worn out parts. Over time, usage can wear out parts or weaken them. Thinness, brittleness, and visible discoloration are good indications that plastic needs to be replaced. Cracked plastic should also be replaced immediately. Inspect other parts, like the hinges, the fasteners on the bottom of the seat, and the nut on the threaded end of the bolt. Replacing these before they degrade could save you a lot of trouble.

Comments

0 comment